- 2,606

- 2,353

- 113

- Location

- Efland, NC

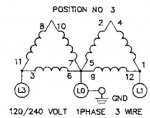

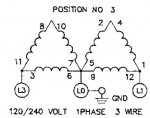

I would check all the wires on the reconnect switch (edit -S8 ) and see if they are in the right places.

Last edited:

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

I mistakenly put S6 in my post above (corrected). You should be working on S8.Time out. Stop and think. The S6 is all about measurement. S8 is all about output. Your problem is in the output side.

| T1-T4 | 0.4 Ohm |

| T2-T5 | 0.4 Ohm |

| T3-T6 | 0.5 Ohm |

| T7-T10 | 0.5 Ohm |

| T8-T11 | 0.4 Ohm |

| T9-T12 | 0.3 Ohm |

And also to ground.You should also verify that there is no connection between each of the windings.

| T1-T12 | 2.5 Ohm |

| T3-T5 | 0.436 KOhm |

| T3-T6 | 0.436 KOhm |

| T3-T9 | 0.436 KOhm |

| T5-T6 | 0.1 Ohm |

| T5-T9 | 0.1 Ohm |

| T6-T9 | 0.1 Ohm |

| T9-T10 | 1.6 MOhm |