Last night I made some good progress on the truck. I got both heads off and put them on the bench. I also pulled the oil pan to see what things looked like under there. I was also curious as to what rod bolts I had in my engine, 6 point or the latest and greatest 12 point. I don't think my engine was ever apart because there is no rebuild tag and it has a date of 7-21-69 cast on the side of the block. Another thing I saw was my oil pressure regulator in the side of the engine is also the early style. So everything to me says the engine was never apart with the exception of me putting head gaskets on it a couple years ago (just as a PM). I did notice the idler gear of the oil pump felt loose as in it walked forward and back on the shaft quite a bit. I don't know what that is all about and it does not seem right, so i will need to investigate that further later.

Cylinder Heads:

After I got these on the bench I was able to look at these further. At first I noticed quite a bit of white powder on the cylinder heads (as shown in the photo) which I contribute that to burning WMO as fuel. I then used my valve spring compressor to remove the valve spring and remove the valve for inspection. I removed the valve and noticed quite a bit of black crunchy baked on oil or whatever it is on the intake valve. This seems odd because the only thing going in the intake should be air. Maybe my turbo is leaking oil a little bit? If somebody knew why I have crud on my intake valve, let me know, because all I can think of is a leaky turbo. I then pulled an exhaust valve I noticed some bad pitting on the valve where it meets the seat. I also wiped the oil off the valve stem and put it back in the head to feel if the guide is worn at all. I am estimating i felt .010' of slop in the valve guide. Just by feeling the valve stem with my fingers (not measuring) I could feel a little wear. So it might be time for new valve guides and exhaust valves anyway. The intakes felt a lot better as far as slop within the guides, which makes sense because they take less abuse. I did not investigate for any cracks on the heads yet between the valve seats. I heard that is a common place for them to crack, but I have not cleaned them up yet.

Above: Intake valve. The valve may look pitted, but its not... It is oil on the surface that I did not wipe off.

Above: Exhaust valve. Notice the pitting.

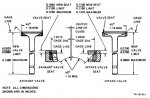

Above: Engine rear to the left, engine front to the right.

I might take tonight off from doing any major work on the truck. 2 nights of beating myself up working on it and I should take a night to clean the house and maybe grocery shop eating mac and cheese for the past couple nights gets old. haha! If I did anything, I could inspect the heads further and clean them up.

If anybody has any questions during my rebuild process, please let me know. I will try to answer them clearly if somebody has questions. Not many people dig this deep inside a multifuel. I will try to post as much information as I can for little tips and tricks I learn along the way.