When I first did mine, I used my "Lincoln Power Grease Pump". I should have paid more attention but I just sat there holding down the switch and that thing pumped in grease like crazy....

... So if you have these seals and listen to Gringeltaubs advice and pump in grease until it comes out back, you will "blow" out your seals also.

...

OK, what if we added this phrase:...."but if you pump in grease

normally (by using a REGULAR HAND PUMP) you will get grease coming out the back, without damaging any seals"...

Think about this, Rusty: how else would the operator be able to "flush" any old grease out of the

inner bearing?

Just for fun, I did some (greasing) "tests", today... (I got curious and wanted to see how hard (or easy) it was to actually "blow out" one of those rubber seals/ shields...

)

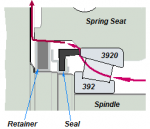

The parts shown in the following pictures all felt very tight, with no play at all. And all of them had the newer, rubber type shield...

Of course, I did

not loosen the cap, on purpose and just pumped grease in, from the bottom.

1st one took a while (to compress the obvious air pockets), but what finally came out at the back side was some dark stuff with the consistency of chewing gum (!) Talk about old grease...! I could actually feel the resistance in the pump, but the thing is, that gum did squeeze out, without doing anything to the shield and washers.

I stopped when it started leaking (fresh grease) at the front. So maybe I blew the cap gasket, but not the rear seal.

2nd one, after about 20 pump strokes, just clean grease (no old stuff) started coming out the back, with very little resistance. After wiping it off, the seal looked as good as before. So, again, no sucess... (in popping the seal)

Of course, isolated test results don't prove anything. And I do acknowledge that things can go wrong, eventually. One single case is proof enough.

Every case may be a bit different. Brand new parts - which most of us don't have - might be a tighter fit, shield to housing?

(as always: "your mileage may vary...")

Again, my humble opinion - after years of working on these things: the whole design is far from ideal, and there is very little we can do to improve it.

One thing I always did was to move that grease zerk out of harms way and place it where everyone can see it - easy to reach and inviting" at least... People in my country don't read TMs, not in English, not in Spanish. But even a moron knows what a grease zerk is for, so there is a slight chance at least that they do add some fresh grease, from time to time!

It has yet to happen that one of those seals popped out, almost like exploded, as seen in Rusty's picture..