So you didn't touch anything on the injection pump itself ? You just replaced the booster pump seal correct ? This truck ran fine before, correct ?

Just trying to find a starting point here.

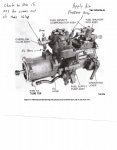

I would try and put air pressure to the injection pumps inlet and make sure air is coming out the pumps bypass valve. This would bypass all the high-pressure side of things.

If you do get air pressure coming out, then we need to dig deeper.

Morning. So last year I took the whole IP out and “rebuilt” it and changed all the O rings and gasket and everything on the head and the pump. I then put the bridle wire or protection wire on the side fuel shut off and had a nice spring action…. I put the pump back in and the truck ran like a champ. It always did.

A couple of weeks ago I noticed I had a leak coming out the bottom of the booster pump.

I took off the IP and took off the booster pump. I put the new seal in and realized I was leaking cause the top bolt of the booster was loose and spinning, I fixed that easy and out back in truck. the ONLY thing I did with that IP beyond the booster pump seal was open the door to see the red tooth, I touched nothing.

When I put the IP back in the truck, the battery and started sound fierce and strong but would NOT start. So we all figured it was the fuel lost its prime.

What “I” did was take the cable off at the end exhaust (the air pressure release from the tank) and made an adapter to my air pressure and ran it.

I took the hose off the IN to the Hydraulic Head and with air pressure got a beautiful steady flow going IN to the hydraulic head.

I loosened all 6 steel lines at the injectors and reconnect the hose going back into the hydraulic head. I ran air pressure..: NOTHING came out those steel lines!!

I then took off, the 2 I could easily loosen, 2 of the steel lines on the hydraulic head side…. Pushed air through. nothing! 1 inch away from where the fuel goes in the HH, I can’t get fuel coming out!

I then opened up the door again where the fuel cut off is and verified it was not stuck. I manually pushed back and forth the lever to see if fuel would pass through then.

Nothing.

Something in that head is blocking/stopping fuel from the Hydraulic Head IN to the “out” of each of the 6 steel lines.

And so at that point, my spirit was and is broken.

. Could I do the same but use my weed sprayer? It’s been empty and cleaned so no residue, so the same thing but hand pump it which creates pressure.

. Could I do the same but use my weed sprayer? It’s been empty and cleaned so no residue, so the same thing but hand pump it which creates pressure.