peakbagger

Well-known member

- 732

- 350

- 63

- Location

- northern nh

For some period of time my SEE had a functioning remote throttle along with the capability to turn on the hydraulic hose tool system. It went away at some point. I have not used the tools but the remote throttle would be very handy when using the backhoe. As a backup I just set the hand throttle and lived with it. I finally spent time to chase the issue down today. I knew the two systems are tied together but had not spent the time with the diagnostics. My first dive was I jumped to a conclusion that the remote throttle switch was bad as these switches going bad are a known issue covered by the Army technical advisory "comic books" (I took the work of another SEE owner several years ago and assembled them into a PDF with an index and links to the topics and stored it in the Misc technical manuals section). I did a quick check with a ohmmeter and it looked dead so I went to remove it and the switch mounting broke when trying to take out the screws. Turns out when I got it out and got at some clean metal that it did work but getting it back in was not going to happen so I made up an adaptor plate and bought a heavy duty outdoor switch. So back to the diagnostiics section of the technical service manual that served me so well years ago when undoing rat damage. This time I also had the student handbook with its SEE specific wiring diagram not included on the overall SEE wiring diagram. The problem is physically locating components like connector "X" which is the interface between the Mercedes harness and the Freightliner US harness. Note I think I found connector X but getting to it would be a very dirty job as my SEE has a long term leaky cylinder that really only leaks when it sits. With the backhoe deployed and looking at the back of the cab, its to the left of the center line of the vehicle roughly in line with the back of the cab hanging below the cab.

I could reach the work light and the hydraulic tools switch from the space around the levers but really could not figure where the wiring went so I removed the protective cover that protects the hydraulic levers for the raising and lowering the backhoe and locking it in position. Once it was off, things made a bit more sense. The remote throttle solenoid is hidden in the upper left hand corner of the housing to the left of the levers, Once I knew it was there, it made some sense. While pulling the switches out I noticed a loose wire just hanging there. I cleaned up the dirt off the wires and found the wire numbers that line up with the Diagram 1 in the Student Handbook. The loose one was 71V which runs from the hydraulic tool switch on the lower right side of the control station to the remote throttle. This is a key wire as without it connected, both the remote throttle switch and hydraulic tool system (that also runs up the throttle) do not run up the throttle. Note there are three places to connect to the solenoid, one is not used . Its noted in the Diagram 1 but it took a bit to figure out which one to hook up to.

The diagnostics section warns that to do the diagnostics, the power and "ignition" key must be on, its true but the warning is not complete. I did a bit of checking with a voltmeter and it looked like that disconnected wire was the problem, so I squeezed the connector a bit to make snugger on the remote throttle solenoid and hooked it up. I really didn't spend any time with the tool circuit. I then started the SEE and the remote throttle would not work meaning no expected increase in power. That took some thinking until I realized that the red air pressure warning light was on. I have been slowly trying to figure the air system out (a work in progress) but one thing I have learned is the SEE routes all the air to the brakes first and once the pressure is up and the warning light has turned off, a secondary air supply valve opens to feed all the other air assisted systems like a remote throttle and possibly the hydraulic tool solenoid (to be determined). So rather than wait for the air pressure to come up, I turned the SEE off and actuated the aux tool switch (and remote throttle switch) and heard a faint but distinct click from a solenoid. If someone was in a noisy area they probably would not hear it. THerefore from a diagnostic point of view, add the precaution to have the air system up to full pressure to actually see if the remote throttle works.

Now it just was time to button it up or so I thought. I put a tie wrap on the loose wire to keep it clear from the hydraulic levers and keep if from having any tension on it. Getting that cover back on took a bit of pushing as it sprung out a bit when taking it off. So everything is good and I start the SEE and let the air pressure come up until the light is off. I then flip the snazzy new chrome remote throttle switch and the engine goes to full throttle. I really wasn't focused on the hydraulic power tools but figured I would give them a try. BAD IDEA. I pulled the tool switch and heard the engine rev and next thing I knew I had a hydraulic leak geyser at one of the hoses. I shut the switch but it was spraying pretty good and I would have been soaked with hydraulic fluid if I went in through the drivers door so I went around to the passenger side and cut the engine. From then on it became a major cleanup projects as it sprayed a 10 foot radius. The CARC paint really takes on some gloss when sprayed with hydraulic fluid . An adjacent long term project, a 1987 Ford Bronco got one side covered and plenty on the ground. The bad spot n the hose was obvious, so I grabbed a bucket and let it drip. Lots of oil absorbent cloths and sawdust were required for the cleanup. The bad spot in the hose was obvious. I had run the system to test it at some point early in the ownership and it held but that was a few years ago.

. An adjacent long term project, a 1987 Ford Bronco got one side covered and plenty on the ground. The bad spot n the hose was obvious, so I grabbed a bucket and let it drip. Lots of oil absorbent cloths and sawdust were required for the cleanup. The bad spot in the hose was obvious. I had run the system to test it at some point early in the ownership and it held but that was a few years ago.

So the remaining mystery is why didnt the tool circuit work previously ?. Looking at Diagram 1, the tool switch is a dual pole switch and the hydraulic solenoid for the tool reel was connected to the switch meaning it should have engaged the tool hydraulic solenoid but the throttle would not ramp up with the remote throttle solenoid disconnected). It was not doing that prior to me getting the remote throttle solenoid working. Info on these Freightliner supplied systems is definitely an afterthought in the tech manuals and I have not found out how it i configured (it may be in there, I just have not found it yet). My pure speculation, is that the hydraulic solenoid may be air assisted from the air discharge of the remote throttle? Therefore, without the remote throttle solenoid working, the hydraulic tool solenoid does not. Note this is pure speculation. It could just as well be that the tool switch was dirty inside and me messing with it cleaned the contacts?. Sadly the student handbook skips over these systems so we may be on our own? (BTW I looked up the hydraulic solenoid in the parts list and it does not look air assisted)

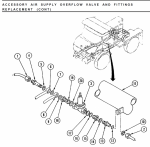

So now that I have partially glossy SEE, I suppose I will either get some new hoses or just cut them back and put some repair couplings on them as the local hose shops will not put new fittings on old hoses (IMHO a way of selling new hose). Looking at the design, those hose ends flop in the breeze whenever the SEE is being moved and a definitely wear spot. The rest of the hose is mostly covered from UV damage so my thought is pull it out a couple of feet and cut them and use a repair coupling on both hoses then rig up a place to hang the hoses. I do have couple of the special Stanley (Eaton) flat face couplings and may just plug them and mount then permanently on the SEE and connect the hose couplings to them to keep them from whipping around. The Technical advisory recommends moving the hose bumper back and connecting the two hoses together and running the system for a few minutes to flush out any stale fluid from the system. This would make even more hose to flip around.

Once I get the hose issue fixed I will reach inside and pull the wire 71V from the remote throttle solenoid and see if I can repeat the tool switch issue.

Hopefully this will save someone else someday and thus the separate thread. Maybe someone else can fill in the mystery on the hydraulic solenoid. I will keep looking and will reply if I find something

I could reach the work light and the hydraulic tools switch from the space around the levers but really could not figure where the wiring went so I removed the protective cover that protects the hydraulic levers for the raising and lowering the backhoe and locking it in position. Once it was off, things made a bit more sense. The remote throttle solenoid is hidden in the upper left hand corner of the housing to the left of the levers, Once I knew it was there, it made some sense. While pulling the switches out I noticed a loose wire just hanging there. I cleaned up the dirt off the wires and found the wire numbers that line up with the Diagram 1 in the Student Handbook. The loose one was 71V which runs from the hydraulic tool switch on the lower right side of the control station to the remote throttle. This is a key wire as without it connected, both the remote throttle switch and hydraulic tool system (that also runs up the throttle) do not run up the throttle. Note there are three places to connect to the solenoid, one is not used . Its noted in the Diagram 1 but it took a bit to figure out which one to hook up to.

The diagnostics section warns that to do the diagnostics, the power and "ignition" key must be on, its true but the warning is not complete. I did a bit of checking with a voltmeter and it looked like that disconnected wire was the problem, so I squeezed the connector a bit to make snugger on the remote throttle solenoid and hooked it up. I really didn't spend any time with the tool circuit. I then started the SEE and the remote throttle would not work meaning no expected increase in power. That took some thinking until I realized that the red air pressure warning light was on. I have been slowly trying to figure the air system out (a work in progress) but one thing I have learned is the SEE routes all the air to the brakes first and once the pressure is up and the warning light has turned off, a secondary air supply valve opens to feed all the other air assisted systems like a remote throttle and possibly the hydraulic tool solenoid (to be determined). So rather than wait for the air pressure to come up, I turned the SEE off and actuated the aux tool switch (and remote throttle switch) and heard a faint but distinct click from a solenoid. If someone was in a noisy area they probably would not hear it. THerefore from a diagnostic point of view, add the precaution to have the air system up to full pressure to actually see if the remote throttle works.

Now it just was time to button it up or so I thought. I put a tie wrap on the loose wire to keep it clear from the hydraulic levers and keep if from having any tension on it. Getting that cover back on took a bit of pushing as it sprung out a bit when taking it off. So everything is good and I start the SEE and let the air pressure come up until the light is off. I then flip the snazzy new chrome remote throttle switch and the engine goes to full throttle. I really wasn't focused on the hydraulic power tools but figured I would give them a try. BAD IDEA. I pulled the tool switch and heard the engine rev and next thing I knew I had a hydraulic leak geyser at one of the hoses. I shut the switch but it was spraying pretty good and I would have been soaked with hydraulic fluid if I went in through the drivers door so I went around to the passenger side and cut the engine. From then on it became a major cleanup projects as it sprayed a 10 foot radius. The CARC paint really takes on some gloss when sprayed with hydraulic fluid

So the remaining mystery is why didnt the tool circuit work previously ?. Looking at Diagram 1, the tool switch is a dual pole switch and the hydraulic solenoid for the tool reel was connected to the switch meaning it should have engaged the tool hydraulic solenoid but the throttle would not ramp up with the remote throttle solenoid disconnected). It was not doing that prior to me getting the remote throttle solenoid working. Info on these Freightliner supplied systems is definitely an afterthought in the tech manuals and I have not found out how it i configured (it may be in there, I just have not found it yet). My pure speculation, is that the hydraulic solenoid may be air assisted from the air discharge of the remote throttle? Therefore, without the remote throttle solenoid working, the hydraulic tool solenoid does not. Note this is pure speculation. It could just as well be that the tool switch was dirty inside and me messing with it cleaned the contacts?. Sadly the student handbook skips over these systems so we may be on our own? (BTW I looked up the hydraulic solenoid in the parts list and it does not look air assisted)

So now that I have partially glossy SEE, I suppose I will either get some new hoses or just cut them back and put some repair couplings on them as the local hose shops will not put new fittings on old hoses (IMHO a way of selling new hose). Looking at the design, those hose ends flop in the breeze whenever the SEE is being moved and a definitely wear spot. The rest of the hose is mostly covered from UV damage so my thought is pull it out a couple of feet and cut them and use a repair coupling on both hoses then rig up a place to hang the hoses. I do have couple of the special Stanley (Eaton) flat face couplings and may just plug them and mount then permanently on the SEE and connect the hose couplings to them to keep them from whipping around. The Technical advisory recommends moving the hose bumper back and connecting the two hoses together and running the system for a few minutes to flush out any stale fluid from the system. This would make even more hose to flip around.

Once I get the hose issue fixed I will reach inside and pull the wire 71V from the remote throttle solenoid and see if I can repeat the tool switch issue.

Hopefully this will save someone else someday and thus the separate thread. Maybe someone else can fill in the mystery on the hydraulic solenoid. I will keep looking and will reply if I find something

Last edited: