- 1,954

- 401

- 68

- Location

- Culver City, CA

UPDATE 18AUG12: The job is done! See page 2 post 19 & 20 for details...

UPDATE 08AUG12: I have pretty much figured this all out. Please read on as I post the details of my progress.

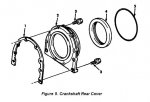

I have removed all components involved to get into the flywheel housing of the NHC250 in my M818. Now, TM -34-1 shows, and I have read it exhaustively, the flywheel housing removed to change out the rear main seal by removing the rear cover/oil seal housing from the block.

However, the TM also shows the seal can be installed after the rear cover/oil seal housing is bolted back into the block. This would lead me to believe that one should be able to remove the seal without going through all of the above trouble.

I can look between the crank flange and surrounding metal (rear cover or seal casing?) and see where the seal material meets the flange. I have made an attempt to remove the seal to no avail and I fear I have fouled something up.

Has anyone tackled this endeavor and, if so, how did you remove and reinstall the rear main seal.

Here are pics of where I am at:

UPDATE 08AUG12: I have pretty much figured this all out. Please read on as I post the details of my progress.

I have removed all components involved to get into the flywheel housing of the NHC250 in my M818. Now, TM -34-1 shows, and I have read it exhaustively, the flywheel housing removed to change out the rear main seal by removing the rear cover/oil seal housing from the block.

However, the TM also shows the seal can be installed after the rear cover/oil seal housing is bolted back into the block. This would lead me to believe that one should be able to remove the seal without going through all of the above trouble.

I can look between the crank flange and surrounding metal (rear cover or seal casing?) and see where the seal material meets the flange. I have made an attempt to remove the seal to no avail and I fear I have fouled something up.

Has anyone tackled this endeavor and, if so, how did you remove and reinstall the rear main seal.

Here are pics of where I am at:

Last edited: