Well with the help of this thread -- I tore the IP head off to replace the 2 0-rings. It went as expected the 2 hr job took about 12

( big learning curve ) the first IP I have torn into.

So after removing heater ect. I start to remove injecter lines from head --- all the lines except one line (#3 had a rain cap on it) were rust welded to the nuts

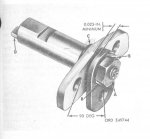

so I remove the lines from the injector --- struggle to line up tooth to mark --- remove hold down nuts and fuel lines ect. remove IP head -- I decide to remove stuck lines from head ( only had to straighten one some --so get stuck lines off and put them in some 30 min rust remover--- hours later still rust welded in place

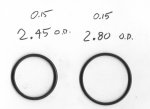

Mean while I locate the larger o-ring right away-- but dont see the smaller one --- so tear into head to find small o-ring hmmmm --Oh there it is still in the housing -- lol -- put head back together. I drive 30 min into town to find o-rings (we are at our farm in rural Iowa not at our home in Florida). Go to Napa first -- no go-- then to big machine shop--- nope

Third try I go to tractor dealer --yea they have the o-rings or at least they measure to specs.

So its back with the booty -- I put rust welded lines back in the head -- and struggle to install head with lines attached

Over an hour later i get the head on and the lines in the injectors

I tidy thing up and get the wife to run the started -- without too much cranking we start to get fuel spitting out the not tight injector line and the engine starts to run -- I tell the wife to shut it off -- I tighten the injector lines and she hits the starter --hmmmmmmmmmmm sounds good -- dont see any fuel leaking

I didnt run it hard but will tomarrow.

Thanks to all for the info and pictures

Mike PS Only fell off the truck once

and one cut on the hand -- even with gloves on --lol