zer0

New member

- 9

- 0

- 0

- Location

- Temple, PA

Hello All.

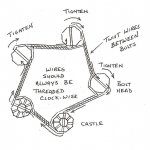

I am in the midst (or well very start of) flipping my hubs. I have done a bunch of searching around and was not able to find an answer so far. I noticed that in the TM it mentions safety wiring the bolts that bolt the hub to the drum. I noticed the heads of mine have holes in them for the safety wire, but, mine was not wired beforehand. I wanted to see, before I went too far, what pattern are people using to safety wire? S wrap, figure 8, etc. Also, is it even necessary? I assume, its int he TM, so it may be important, but, I thought I would check with people with more experience with this than me before I got too far afield.

Thank you

I am in the midst (or well very start of) flipping my hubs. I have done a bunch of searching around and was not able to find an answer so far. I noticed that in the TM it mentions safety wiring the bolts that bolt the hub to the drum. I noticed the heads of mine have holes in them for the safety wire, but, mine was not wired beforehand. I wanted to see, before I went too far, what pattern are people using to safety wire? S wrap, figure 8, etc. Also, is it even necessary? I assume, its int he TM, so it may be important, but, I thought I would check with people with more experience with this than me before I got too far afield.

Thank you