Speedwoble

Well-known member

- 606

- 303

- 63

- Location

- New Holland, PA

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

My gasket just ate itself recently, so perfect timing on these rolling out! Thanks!The first Flexible cab gasket was on the 3D printer on Sunday. I will try to pick it up today.

That’s awesome sauce! I’ve always wanted to play with one of those scanners. +1 million for the quick-tach. Pull the trigger on that one.No update in a while. I printed some cab gaskets and sent them to a member to try. I'm now with some extra time on my hands due to Covid, so I thought I would get back to this. However currently I am locked out of access to the 3D printer that makes them, so I can't print my own to try!

I do have a spare stainless airline, so I will try installing the air line on my own truck to verify fitment. Then i can get more of those made.

I welded up the jig to speed up the process of making cab tilt brackets and I cranked out a large batch. I also made 8 pairs for the 406/416 unimogs. All of these are currently at the powdercoater to get coated.

Lastly I borrowed a 3D scanner and will be scanning some parts. Backhoe bucket and Ripper shank done. Next I will scan the loader bucket and try to come up with a model for the quicktach that may be a little cheaper and require less individual fab work. I plan to scan the front end of the mog for designing my 18K lb winch mount that will fit with the loader. I plan to scan the Loader attachment at the front of the frame and the backhoe attachment at the rear for future attachment design. Anything else I should scan while I have a moment? I was thinking about the Engine and engine cover so I could see how tight it is for a future turbo install. However, based on how slowly I get to these things, that may be a few decades.

Looks cool! I have printed out some pla for my 51' Gm bus window hinges, plan on using greensand molds to cast them in aluminum.No update in a while. I printed some cab gaskets and sent them to a member to try. I'm now with some extra time on my hands due to Covid, so I thought I would get back to this. However currently I am locked out of access to the 3D printer that makes them, so I can't print my own to try!

,

,

I think you should do very well with these. I just asked for a quotation from the original manufacturer. They have 3 in stock at $750.00 each! It's no wonder our taxes are so high.Update on 2 of the projects. I test fit the 3/8" stainless steel line and verified it fit and did not leak. Then I became aware of another tubing mfg around me that could make a tube out of 10mm, the same as original. I contacted them to get a prototype, but it is more than double the cost of the other supplier, so I am going to pursue the original design shown in post #21. I will get a first production run of 10 stainless cross-over pipes made.

For the Cab gasket, I had originally duplicated the function of the original gasket via flexible 3D print. However I shipped the prototypes to a SS member who hasn't installed them yet,

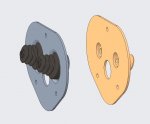

In the mean time, I had a better idea. I am going to make the main portion in a firmer urethane and the softer bellows will use a pair of VW master cylinder bellows so they can be replaced in the future.

View attachment 809475

I am interested in one of your cab gaskets when ready. However, how will the firmer urethane fit over the large third hole? There are brackets on both ends of the large tube.For the Cab gasket, I had originally duplicated the function of the original gasket via flexible 3D print. However I shipped the prototypes to a SS member who hasn't installed them yet.

In the mean time, I had a better idea. I am going to make the main portion in a firmer urethane and the softer bellows will use a pair of VW master cylinder bellows so they can be replaced in the future.

View attachment 809475

Also Intrested!!!Hey Speedwoble,

It's been a while on this thread, just curious how you're coming with all of your accessory projects? Because I'll keep buy what you're cranking out!

Just take my money already,

SJ/JD