peakbagger

Well-known member

- 732

- 350

- 63

- Location

- northern nh

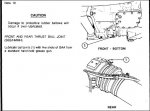

I have been spending some time locating all the grease points. There is reminder in the PS articles about the two grease points that tend to be forgotten under the center of the truck. They put grease to the sealed front ad rear prop shaft joints. One is fairly obvious but the other one took awhile even with the diagrams in the TMs. I couldn't see it underneath. After feeling around for awhile I could feel the fitting on the top of transmission casting but getting a grease gun on it wasn't going to happen. I finally figured out that if I rotate the backhoe to deployed conditions I can reach down behind the tool box and jerry can mount and just reach the fitting. I expect it doesn't get much grease given that the manuals don't give this hint. The PS article warns not to overgrease, just 4 to 5 pumps with standard grease gun.

The fitting in question is the rear one.

The fitting in question is the rear one.

Last edited: