banditt1979

Well-known member

- 273

- 738

- 93

- Location

- Cincinnati, OH

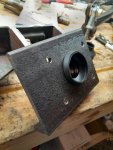

A while back I rebuilt the air pack that came with the truck. The gasket that came with it for the rear plate was too small and broke when I tried to install it so I reused the old one. Then I removed the air pack and installed a rebuilt unit thinking there was something wrong with it. Removed the rear cover to inspect and tore the old gasket. Well this evening I carefully made a new one. I used my compass from college to make a circle on some gasket material I had (again, hot rod days) 4 1/2 " diameter and used an xacto knife set I bought in Pigeon Forge, and carefully cut the inner diameter. Checked to make sure that was good then notched the areas for the studs. All went well and another obstacle out of the way!

Attachments

-

35.3 KB Views: 14

-

47 KB Views: 16

-

130.3 KB Views: 15