First off, sorry dabtl, this is getting way more technical than the poster probably though it ever would. I'm not advocating removing the starter relay to anybody, that relay may well be what is causing the problem being discussed.

cranetruck said:

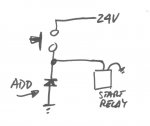

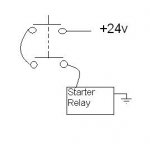

The deuce starter has two coils, one pull-in and one holding, but you still need to design with the pull-in in mind and the spec sheet actually calls out a max of 70 amps peak IIRC and the deuce starter relay is rated at 50 amps.

Thanks for that info about the starter. I was assuming that was the solenoid configuration used, but I wasn't sure. Yes, you are right again about needing to design with the pull in current in mind, but going back to the bit about the starter relay bypass, it would work just fine without the relay, but it would definitely shorten the buttons effective lifespan. The only conceivable time that the wire size would cause an issue would be if the plunger on the solenoid actually became stuck and would not pull in, simply because the higher current is there only for a matter of milliseconds under normal operation. Please know, I'm not arguing any points with you, I think the information you are providing is spot on. I'm simply saying that bypassing the relay would have little noticeable affect on the operations of the button or wiring, but that also makes what I said earlier about using a firm, crisp depression of the button all that much more important.

If you had the button on a test bench hooked up to a starter, when the button is depressed, even with the relay in place and operational for just the split second before the contacts of that button were fully closed; and again in the split second after the button was released, you would see a small arc between the contacts. This arc would be greater if the button was bypassing the starter relay because of the higher current draw, it's just the nature of DC current. It arcs a lot more than AC does. That arcing causes corrosion on the button contacts and causes them to not be as conductive as they should be. In an industrial setting we use 2 sets of contacts in series with each other for anything dealing with DC just to help break that arc as soon as possible.