davidkroberts

Active member

- 1,452

- 24

- 38

- Location

- west tennessee

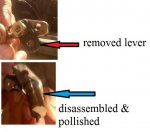

Well this has been covered here before and thank you all who told us about this problem. Once we knew what it was it was about a 20 minute fix. Thanks Gimpy and others who contributed. Im just adding pics because i didnt see any when i searched through here.

The first problem we had was the truck started great after sitting for a few months. Once it caught it immediately went into full throttle. Not wanting to blow the motor i pulled the stop engine cable. The truck didnt start again after that. We tracked the problem to the injection pump after verifying the filters and fuel pump were good. Turns out the engine stop lever was jammed in the kill-engine position. After manually pulling the lever back to run and starting the engine again it went back into a runaway diesel situation. We killed the motor again and again it wouldnt start. The cable was jammed again.

Turns out it was the lever that runs into the injection pump behind the engine start cable assembly. The entire assembly needs to be pulled out and seperated and cleaned. The t-bar looking thing in the pictures below needs to be completely disassemled and soaked to remove the trash and coorosion that keeps it from turning freely. Take pictures prior to disassembly because it needs to be reassebled exactly as it came apart. We used Naptha to break everything loose then allowed it to dry then coated everything with WD-40 to remove any trace of junk and naptha. When its reassembled it needs to move very freely with no noticable resistance when we took it off you almost needed a wrench and brace to move it. When removing the assembly the safety wire needs to be cut and the entire thing pulls straight out once the retaining ring is removed.

We reassembled and adjusted the idle once it was running and everything worked great

The first problem we had was the truck started great after sitting for a few months. Once it caught it immediately went into full throttle. Not wanting to blow the motor i pulled the stop engine cable. The truck didnt start again after that. We tracked the problem to the injection pump after verifying the filters and fuel pump were good. Turns out the engine stop lever was jammed in the kill-engine position. After manually pulling the lever back to run and starting the engine again it went back into a runaway diesel situation. We killed the motor again and again it wouldnt start. The cable was jammed again.

Turns out it was the lever that runs into the injection pump behind the engine start cable assembly. The entire assembly needs to be pulled out and seperated and cleaned. The t-bar looking thing in the pictures below needs to be completely disassemled and soaked to remove the trash and coorosion that keeps it from turning freely. Take pictures prior to disassembly because it needs to be reassebled exactly as it came apart. We used Naptha to break everything loose then allowed it to dry then coated everything with WD-40 to remove any trace of junk and naptha. When its reassembled it needs to move very freely with no noticable resistance when we took it off you almost needed a wrench and brace to move it. When removing the assembly the safety wire needs to be cut and the entire thing pulls straight out once the retaining ring is removed.

We reassembled and adjusted the idle once it was running and everything worked great

Attachments

-

66.5 KB Views: 381

-

61.6 KB Views: 348

-

45.5 KB Views: 353

-

74.9 KB Views: 359