These are some pictures of a Heavy Duty TH400 case. The first 2 pictures shows the 8 bolt holes for mounting the front pump assembly (TH475 models only) . The third and fourth pictures show the extra strength on the flange to mount the aluminum torque converter cover and the support it provides for the transmission. Note the brace-rods going from the cover to the engine mounts. Pictures five and six show the raised numbers "39" which says this is a Heavy Duty case. Most cases with the raised numbers on them are Heavy Duty cases. They are made with extra thick housings and flanges. Usually the raised numbers are 30's or 40's numbers.

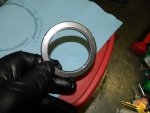

The last picture shows the holding brackets used in repairing the GM transmissions. I highly recommend you find some if you plan on rebuilding more then a couple GM transmissions. The black one is for the older transmissions stopping at the TH400. The blue one is for the 4L80E to 6L90E transmissions.

Most all the military TH400's have been the heavy Duty models though I have seen some M1008 units that where not. Most all do not have the 8 bolt pump mounting though. That was used on the TH475 models only. I have been able to drill out the pumps and housings to make them the stronger TH475 units though.

If anyone is interested I will post some pictures showing how this is done.

I will be posting some pictures of the performance parts that will increase the durability of the TH400 later. My camera's batteries crapped out on me when I was taking these pictures.