4 batteries were chosen to meet a particular milspec requirement like being able to set for a month on the Siberian step in wintertime and still be able to crank the engine long enough to start it with no supplemental heat. Un fortunately the person designing the electrical system wasn’t in on this plan and didn’t put an alternator in large enough to comfortably handle this situation. This is the kind of error that recalls and class action law suits are made of out in the real world

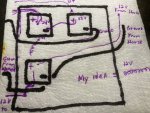

you can very comfortably drop to two batteries in series for 24 and take the 12v out of the middle to feed the 12v circuits. To answer your questions:

1. Only 2 or 4 batteries are used. The alternator is designed to operate as a simple battery balancer and is looking to supply 2 batteries of equal size placed in series.

2. Yes, two 8D’s would be more capacity than two of anything else. Keep in mind that the alt is strained keeping large batteries fully charged. Cat specs a pair of group 31 lead acid wet batts(100AH) for the power equipment that uses these engines. A pair of group 31’s is also a good match for the alternator. A pair of group 31 AGM’s will push the alt over 100% load. As for cranking capacity, my 3116 pulls a brief peak to about 290A when starting to crank, but averages just over 150A when cranking… If I was worried about being able to start when cold, I would take steps to mitigate that instead of oversizing the bank as there are other disadvantages besides alt overload.

No you do not want to mix battery capacities. One will top off faster than the other and then start to overcharge, while the other larger battery may have trouble reaching a full state of charge. AGMs are still lead acid, it is just their internal design gives them a lower internal resistance so they can feed more current and can accept/demand more current(nearly twice as much) when charging for a given size battery compared to a normal wet plate cell design.

You certainly don’t want to mix those different types. This same thing can happen when you have a failing battery in parallel with a good one. The failing battery gets overcharged and gets progressively worse, and the good battery never gets fully charged and quickly joins the other bad one…

Unless you have a 260A A1R alt, 4 discharged wet cells is an overload for the alt, 4 discharged AGM’s is an extreme overload for the standard 100A alt. The oversized bank and its associated problems are where the LBCD came from, to disconnect a dead or damaged battery bank from the alt to keep from cooking it…

What kills lead acid batteries is time spent below a full state of charge. The deeper the discharge below full the faster their life clock ticks away as the sulfation builds up robbing them of plate surface area/capacity. Unless you run these trucks for hours at a time, frequently, or keep a maintenance float charge on them when parked, it is more than likely that the batteries rarely if ever reach a full state of charge. The 12v side also has more electrical load so there is less available power from the alt on that side. The 12v side also has a small vampire load… the combination of oversized batt, undersized alt and low run hours is probably why these trucks have so many battery/alt problems. They changed the charging system design twice, so at least they realized something was wrong. They added the LBCD(monitors alt load and disconnects the batts when it becomes overloaded) on the A1, and finally fitting a 260A alt on the A1R. That alt was pretty-much a necessity as the military introduced the AGM batteries…

if I was wanting more house battery, I would have more house battery and not rely on regularly mixing house and service… But maybe that’s just me…