frioman

New member

- 97

- 0

- 0

- Location

- Houston/TX

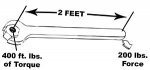

I don't have a 450 pound torque wrench, but if I use the formula Distance = Torque/Force, I should be able to stand on a cheater pipe 2.43 feet from the lug wrench with my 185 pounds of weight and create 450 foot pounds of torque.

450 torque divided by 185 pounds (my weight) = 2.43 feet.

This web site has a torque distance calculator with the answer in Meters -- http://www.calculatoredge.com/new/torque.htm#distance

This web site converts meters to feet -- http://www.metric-conversions.org/length/meters-to-feet.htm

I hope this helps.

450 torque divided by 185 pounds (my weight) = 2.43 feet.

This web site has a torque distance calculator with the answer in Meters -- http://www.calculatoredge.com/new/torque.htm#distance

This web site converts meters to feet -- http://www.metric-conversions.org/length/meters-to-feet.htm

I hope this helps.