rsh253

New member

- 142

- 1

- 0

- Location

- Fort Mill, South Carolina

I felt a vibration for 15-20 seconds, and then it sounded like an explosion.  It took a few seconds, but then I realized the engine wasn't driving the rear wheels any longer. Luckily, a 13,000 lb vehicle traveling at 50 mph can coast for a long way and I was able to pull off the road onto a nice grassy spot.

It took a few seconds, but then I realized the engine wasn't driving the rear wheels any longer. Luckily, a 13,000 lb vehicle traveling at 50 mph can coast for a long way and I was able to pull off the road onto a nice grassy spot.

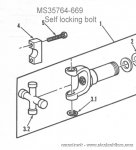

My driveshaft let go from at the axle flange, banged around on the frame and then the transmission yoke let go. On its way out, the drive shaft also hit and blewout one on the inside rear tires. I think the bolts on the rear flange were loose. When I replaced what was left of the shaft, the front bolts were not particularly tight.

One of the photos is of the truck frame with the very clear imprint of a Grade 8 bolt head.

Luckily I was able to get the truck home by engaging the front axle. I was able to buy a good used driveshaft on eBay.

It was an "interesting" experience.

-Russ

My driveshaft let go from at the axle flange, banged around on the frame and then the transmission yoke let go. On its way out, the drive shaft also hit and blewout one on the inside rear tires. I think the bolts on the rear flange were loose. When I replaced what was left of the shaft, the front bolts were not particularly tight.

One of the photos is of the truck frame with the very clear imprint of a Grade 8 bolt head.

Luckily I was able to get the truck home by engaging the front axle. I was able to buy a good used driveshaft on eBay.

It was an "interesting" experience.

-Russ

Attachments

-

79.1 KB Views: 561

-

74.4 KB Views: 559

-

78.2 KB Views: 559

-

77.9 KB Views: 557

-

80.9 KB Views: 557