That looks good but...

In the Netherlands, I am allowed only to drill in the middle zone of the side flange of the main frame and the bolts should not be completely at the lower end of the side-rail; more or less in the middle is the best.

Together with the DoT, I looked at that idea for a side rail as you drew as well for mounting the 5th wheel (much easier for swapping).

The end conclusion was that you would need at least a 3 inch high high-quality steel side-rail, 4 inch would be better. You also have to put spacers between it and the frame to go around those @#$#@ handles (or take those off), the support brackets, and the rivets for the frame cross-beams. Seeing all those bolts and rivets already there, and seeing the civic European solution and the standard M818 set-up, they agreed that 5 holes from above would be the better way to go.

Pic 1: civic standard EU side rail for fixed or movable 5th wheel. Watch how high this rail is. Installing that on this existing frame following Dutch rules is a serious pain.

Pic 2: side rail fixed to an M818 tractor. The rail actually is quite small and sits very high on the main frame to go around the handles and support brackets. That was not acceptable for the Dutch DoT.

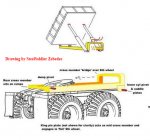

Pic 2: my M51A2 preparing for fitting the 5th wheel. On the top part of the photo you see the spacer wood that normally rests between main frame and sub frame of a dump truck. You see the six bolts for connecting the spacer plate. In the end, we used only 5; the last bolt from the back (left side of picture) was left out. Too much rivets around it and two bolts there would not have been much better than only one.

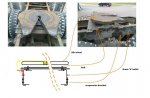

To go back to the hydraulics mentioned earlier. One way of maybe simplifying the hydraulic problem would be using a central front telescopic cylinder. You would have to strengthen the bed but it would at least stop the cylinders from interfering with the fifth wheel or running outside the frame and interfering with the wheels when off-road.