- 2,114

- 565

- 113

- Location

- Davis County, UT

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

You got one of the "lucky" ones with an RTV top. That stuffs a nightmare... all you can do is pry and work it over. That right side is always stuck the worst. Thankfully its not on the majority of machines.Thank you so much Guyfang and Kloppk (and everyone else too!) for taking so much of your time to share your expertise here. I sincerely appreciate it.

I did open up the top of the control panel, well, partially at least, because it was REALLY stuck down to the right side and I didn't feel like getting aggressive with prying it apart if I didn't HAVE to.

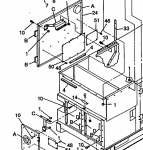

View attachment 915581

I did not find any signs of wire chafing, and I sprayed Deoxit contact cleaner on each of the connectors inside. I also sprayed the shaft of the Reconnection Switch and turned it back and forth a few times to hopefully work the contact cleaner into it as well.

View attachment 915580

https://www.amazon.com/gp/product/B00006LVEU/

Thank you for the investigation. It is always curious what the history of the machines are and who did what/when. Whether a previous owner put that fuse in or it was that way when surplused, all I can tell is that the fuse looked old. (I suspect most likely is a used/old fuse was put in to sell the unit). Glad that to hear that it likely didn't hurt anything.I think the fuse was/is a (Mersen) Ferraz Shawmut "Amp-trap" ATX-3, where the X is missing, perhaps "M" for midget (1 1/2" long)?

There are eBay listings for Ferrari ATM-3 listings, if you want to look it up.

e.g. https://www.ebay.com/itm/383671751698?

That would have been a fast acting fuse;

Ferraz Shawmut / Mersen Sales | ATM Series / 600VAC - 600VDC

Ferraz Amp-trap midget fast-acting ATM fuses are rated 600V AC, with a 100kA interrupting rating. These ratings give the ATM a wide range of applications not covered by other midget fuses.ferrazshawmutsales.com

I could be wildly off here.

All the best,

2Pbfeet

I have not yet read about there being differences on how the panels are sealed (I actually didn't expect there to be anything). Should I be scraping it off and putting in some other low profile seal?You got one of the "lucky" ones with an RTV top. That stuffs a nightmare... all you can do is pry and work it over. That right side is always stuck the worst. Thankfully its not on the majority of machines.

The %Load function on my system is measuring the voltage/current that each winding pair is contributing to the load. It's actually measuring the voltage at the 3 different phase load inputs to K8 the overload relay from the burden resistors.

When in 120 or 120/240 mode the %Load readings from my board should all be about the same value since each winding pair is equally supporting the load.

Yes, you need to perform the calibration function to tweek my system to provide matching accurate readings.

As for the Hz reading the set has to output near proper voltage for the Hz reading to work. Way too low a voltage will cause the inf reading.

The 150 ish % load reading and your contactor opening are likely due to a contact issue in S8. When in 120 or 120/240 contacts 13 and 14 should close which puts burden resistor R13 in parallel with R12. If the resistor paralleling doesn't happen the reading on L3 will be twice the other readings and cause the set to trip an overload. S8 may need cleaning and exercising to correct the issue. Deoxit.

The sets %Load meter only displays the load on one winding pair when in 120 or 120/240.

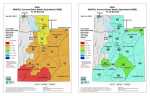

I found a warmer day when it wasn't snowing or raining for me to take the top off the green 803. (Utah has had a very wet second half of winter) water supply in January 04th, 2024 vs Feb 16th, 2024 (percentage totals based on the average Snow Water Equivalent from 1991 to 2020)Originally, There was a seal up top, sealing the panels to the control box. In the -24P, Fig. 5, Item #4. If you look at all the parts breakouts for the metal housing, you will find that part number 20941 is used all over the set.

4. MOOZZ MOO MOOZZ 30554 88-22705 .SEAL, DOOR MAKE FROM P/N 20941 (56329), AS REQUIRED.

So, most people did not want to order a non NSN item, and used RTV. Sadly, those people are the ones who did not RTFB. Every parts TM, has a "Bulk" section at the end of the TM. There, it will give you about the same info as the parts break out. BUT, if you RTFB farther, and go to: CROSS REFERENCE INDEXES NATIONAL STOCK NUMBER INDEX section, and look up the part number 20941, it gives you an NSN of: 5330-01-367-6329. Farther digging tells you, the UNIT of ISSUE is in feet. And thats the reason there is RTV on most gen sets instead of the seal. The seal worked well. I put a tiny dab of, Yes you guessed it, RTV to hold the seal in place. It had tape on the back side. Peal the pape off and press the seal down. I found the tape was not real good. so a tiny dad of RTV smeared on the metal parts held it on. Let it dry, and you never had to fight the RTV monster to get the top off.

You lived here before I was a twinkle in my mother's eye.I lived for a short time in Roy, Utah. First snow I ever saw in my life, and i was 17 years old. Nice place to live, or at least 50 years ago.

Good knowledge there, thank you. I have literally been doing it wrong the whole time. Well, either way, shouldn't be a problem for a while!The best way to handle those panel screws is always hold the Phillips head and turn the nut with a wrench / socket.

Don't hold nut and turn Phillips head, chances are you'll strip the heads.