- 2,113

- 563

- 113

- Location

- Davis County, UT

I'm not te fastest with this project but I've also included restoring my hard top as part of this. Basically, I don't want to have to take the gun ring off again

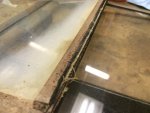

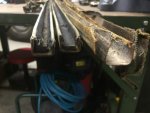

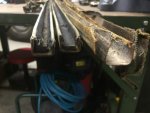

I've been working on the section of the hard top with the sliding rear window. Like most folks, my rear sliding window is in pretty sorry shape, but I think it could still be worse. I had to cut off all the exterior screws holding the water channel on (above and and outside from the sliding window. (sorry, no pics!)

After that water channel was out I was able to unscrew the little #6 screws on the inside that held the windows in place and remove all the window channels. The bottom runs were decimated, but the top ones not so terrible for 44 years (they had less water to deal with I'm sure).

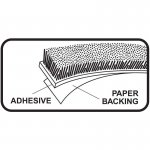

FYI, the side door window channel is not the same as the rear sliding glass channels. New side door window channel is seen on the left. Note, it is felt lined on all 3 sides while the sliding window uses a felt bottom with pile sides.

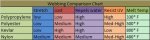

I began a multi-day hunt trying to find an exact match - I had difficulty in even knowing the right words to search for ("Window Channel & Felt Run" or "pile & felt window channel"). To the best of my measuring capabilities, the stock deuce rear window channel is 3/4" wide, but I absolutely could not find channels that wide. So I gambled and ordered 5/8".

The dimensions of my window channels:

The best match I found was a product designated across multiple vendors as "8A1":

The cheapest I found:

http://www.cpidivisions.com/product/unbeaded-glass-channel-96-9/

(CPI was awesome enough to call me and tell me it was back ordered and it'd probably be 2 weeks before it arrived)

So I actually ordered two 72" strips from here (Yay for natural 2-day shipping from Southern California to Utah):

http://www.jjautofabrics.com/8a1-unbeaded-window-channel-72/

(Note: JJ Auto Fabrics told me they did have 96" channels but due to shipping charges they would have been cut in half.)

Ordering 2 of the 72" strips leaves me with exactly zero to spare, and might make the sides 12-1/4" long when accounting for the cut (unless I can just use tin snips). No mistakes now!

(29.75 + 29.75 + 12.375 = 71-7/8")

----------

Update: 05/17/2016

See post #52 below for pictures of a test fit with the windows.

I've been working on the section of the hard top with the sliding rear window. Like most folks, my rear sliding window is in pretty sorry shape, but I think it could still be worse. I had to cut off all the exterior screws holding the water channel on (above and and outside from the sliding window. (sorry, no pics!)

After that water channel was out I was able to unscrew the little #6 screws on the inside that held the windows in place and remove all the window channels. The bottom runs were decimated, but the top ones not so terrible for 44 years (they had less water to deal with I'm sure).

FYI, the side door window channel is not the same as the rear sliding glass channels. New side door window channel is seen on the left. Note, it is felt lined on all 3 sides while the sliding window uses a felt bottom with pile sides.

I began a multi-day hunt trying to find an exact match - I had difficulty in even knowing the right words to search for ("Window Channel & Felt Run" or "pile & felt window channel"). To the best of my measuring capabilities, the stock deuce rear window channel is 3/4" wide, but I absolutely could not find channels that wide. So I gambled and ordered 5/8".

The dimensions of my window channels:

- Top and bottom (4 total)

- 29-3/4" long x 3/4" wide x 1/2" tall

- Sides (2 total)

- ~12-3/8" long x 3/4" wide x 1/2" tall

The best match I found was a product designated across multiple vendors as "8A1":

The cheapest I found:

http://www.cpidivisions.com/product/unbeaded-glass-channel-96-9/

(CPI was awesome enough to call me and tell me it was back ordered and it'd probably be 2 weeks before it arrived)

So I actually ordered two 72" strips from here (Yay for natural 2-day shipping from Southern California to Utah):

http://www.jjautofabrics.com/8a1-unbeaded-window-channel-72/

(Note: JJ Auto Fabrics told me they did have 96" channels but due to shipping charges they would have been cut in half.)

Ordering 2 of the 72" strips leaves me with exactly zero to spare, and might make the sides 12-1/4" long when accounting for the cut (unless I can just use tin snips). No mistakes now!

(29.75 + 29.75 + 12.375 = 71-7/8")

----------

Update: 05/17/2016

See post #52 below for pictures of a test fit with the windows.

Last edited: