As you know, the top rail of a cargo bed is not strong .. I have not installed rings on my 6x6's but I have in one of the box trailers, to secure heavy LTL palletized cargo (truck & equip parts) and hauled a whole rolling jeep in there once... Wooden hardwood floor thus I drilled and Grade-8-bolted the rings down thru the floor into the steel crossmembers of the trailer, tight to the outer rail at the wall where strongest ..

Perhaps bolted thru the crossmembers on a deuce bed would suffice, but Mullaney is correct, to the (bed)frame is better .. truck frame won't do because it needs to flex and there's that spring-loaded "floating" front bed mount to contend with.. Besides, drilling a truck frame is usually viewed as a a no-no ..

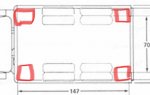

Seems to me what would also suffice is if an adequate amount of 5/16" plate (or larger) was welded to the floor and walls at the bed corners, and both the rings to those. but i would be concerned about the tailgate area being not as strong as the front corners due to the nature of it...

Of course we need to be more-worried about keeping a load from moving forward as opposed to backwards, unless your deuce can do wheelies and jackrabbit starts