- 3,204

- 4,841

- 113

- Location

- Olympia/WA

24V has half the amps.Thanks for your view. That bit on hot for the disconnect is what I would have done too but it seems a number of 4WD sites say negative. I am going to disregard that nonsense as internet stupidity.

And I am in the camp of "no" on breaker or fuse. With potentially a 500 A load at peak, I feel like I will trip the fuse/breaker no matter what happens.

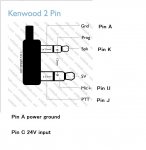

My 12k lb milemarker electric is rated for 185 amps on 24V at full load. The 12V version is 370 amps.

On a 12V system, especially if it's a single battery, you're going to be drawing it down quite a bit on a longer pull, and the more the voltage drops, the higher the amps will be. On 24V it's not going to be as bad with the dual batteries to make 24V.

I've done a few pulls, but haven't maxed it out, and have enough rigging that it's unlikely that I will need to (4 pulley blocks, 150 feet extra line, multiple straps, etc)

together.

together.