Jim Hunter

New member

- 266

- 0

- 0

- Location

- Stationed at Ljubljana , Slovenia

Hello guys,

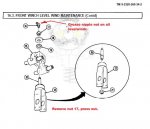

I recently bought two of them and the rollers bearings at both are frozen and needs replacement.

Any source to get them ?

Thank you,

jim

I recently bought two of them and the rollers bearings at both are frozen and needs replacement.

Any source to get them ?

Thank you,

jim