TM-9-2320-289-34 3-48. WATER PUMP REPLACEMENT.

1. Cooling system drained.Fan removed, Fan shroud removed. Right side alternator bracket removed Power steering pump removed

Materials ; water pump gasket. Carb cleaning compound. Anaerobic sealing compound. Pipe sealant

2. Loosen clamp and disconnect crankcase depression regulator valve hose from oil filler tube (4). Remove 2 nuts (12), oil filler tube, and grommet (11) from water pump plate (5).

3. Loosen clamp (7) and disconnect thermostat bypass hose (6) from water pump (

. Loosen clamp (9) and disconnect radiator outlet hose (1 O) from water pump.

NOTE ; Ensure that a suitable container is used to catch coolant as water pump plate is removed. Ensure that position of all bolts, studs, and screws is noted for Installation.

4. Remove 2 oil filler tube studs (16), 4 bolts (17), stud (23), 2 screws (24), long screw (21), long bolt (22), and 2 studs (13), Remove water pump plate (5) and water pump (

from crankcase cover (1

.

5. Remove 7 bolts (19) and separate water pump (

, water pump gasket (20), and water pump plate (5). Remove nipple (15) and plug (14) if damaged or if replacing water pump. Discard water pump gasket.

Clean anaerobic sealing compound from all sealing surfaces. Clean oil from all surfaces with carburetor cleaning compound, Clean pipe sealant from crankcase cover (1

and threads of all bolts, screws, and studs.

INSTALLATION

1. Install nipple (15) and plug (14) on water pump (

with pipe sealant, if removed. Assemble water pump plate (5), new water pump gasket (20), and water pump with 7 bolts (19). Tighten bolts to 20 Ib.-ft. (27 N.m)

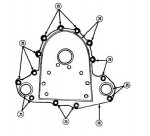

2. Apply anaerobic sealing compound (25) to crankcase cover (1

in pattern shown.

WARNING Avoid skin contact with anaerobic sealing compound. Immediately wash off skin

3. Apply pipe sealant to threads of bolts (17). Apply pipe sealant to oil filler tube studs (16) and stud (23) on portion of threads installed on crankcase cover (1

.

4. Install water pump on crankcase cover (1

with long bolt (22), long screw (21 ), 2 studs (13), 2 screws (24), stud (23), 4 bolts (17), and 2 oil filler tube studs (16). Tighten bolts (17) and stud (23) to 35 Ib.-ft. (47 N.m). Tighten all other bolts, studs, and screws to 20 Ib.-ft. (27 Nom).

5. Connect radiator outlet hose (1 O) to water pump (

and tighten clamp (9). Connect thermostat bypass hose (6) to water pump and tighten clamp (7).

6. Install grommet (11 ) on water pump plate (5). Install oil filter tube (4) on water pump plate with 2 nuts (1 2). Connect crankcase depression regulator valve hose to oil filler tube and tighten clamp.

There's a weird bug which replaces the number 8 with a smiley thing. Can't seem to change it. Who uses these things..they should be banned.