- 10,896

- 7,499

- 113

- Location

- Camp Wood/LC, TX

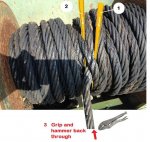

Any tricks to untangling this? Burn it off? Pry bars? The cable goes under a subsequent wrap. Thanks Army. On 916 drag winch, 45K.

Attachments

-

95.3 KB Views: 96

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

IIRC, the TM says to not unwind with power but instead to drag the cable out. Is this why?That condition makes a good winch man shudder. Of course, a loosely wound winch is the cause when a heavier then usual pull is applied. A procedure that can cause a loose wound winch (that is hard to detect), is to do a "power-out" (as if letting down a load), but "power-out" too far. It will loosen everything/all wraps, but still look nice & even - then the next Guy comes along.....

NB. Wrap an oily rag around free cable end before using grippy [Mole-] wrench.

NB. Wrap an oily rag around free cable end before using grippy [Mole-] wrench.No level wind or tensioner on a M916...No one has mentioned this - but I'd take a serious look at the levelwind (and tensioner). This shouldn't have happened if they were working properly - unless some idiot powered-out without pulling the slack cable from the fairlead, then winding back in .... somehow????