Migginsbros

Well-known member

- 2,414

- 7,581

- 113

- Location

- Berlin-Germany

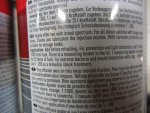

We call it Dieselpest (Black death). Bacteries live in the small zone of water (condense) and the biologig parts in the diesel. This Life means (edited) eat and -get off that stuff- ( don´t no that we don´t use s-h-i-t as a word without becomming 4 stars), thats it. You can´t get it off by cleaning and drying. You must use the chemicals, i think. We use it also to preventation.

The other Bottle is an aditive to make the diesel flow in winter.

The other Bottle is an aditive to make the diesel flow in winter.

Last edited: