Thanks. I'm about 180lb and it holds me standing on it. If I were to do it again I would put a piece of 1" flat stock across the top instead of the small round bar I had laying around, but its functional none-the-less.That's a great looking rack you made. Looks like it could be used for all kinds of items. You have an estimated maximum load for it?

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

What have you done to your HMMWV today/lately

- Thread starter Warthog

- Start date

More options

Who Replied?Victorkilo31

New member

- 82

- 0

- 0

- Location

- San Diego CA

That's not bad at all. Pretty useful load rating then.

Last edited:

Another Ahab

Well-known member

- 18,129

- 4,905

- 113

- Location

- Alexandria, VA

6% humidity?!What is this humidity you guys speak of?

I'm at 6% right now (zip 87144).

Wake up with bloody nose almost daily since it's so dry.

That sounds so low like it might even be dangerous.

I don't think I ever was in humidity that low. Is that normal over your way?

Victorkilo31

New member

- 82

- 0

- 0

- Location

- San Diego CA

It was nice when it was under 10 when I lived in Cali desert. Swamp cooler worked great when it was that dry and helped keep my bloody noses to a minimum at home

Mario

Active member

- 325

- 89

- 28

- Location

- Rio Rancho, NM

High desert here in New Mexico.6% humidity?!

That sounds so low like it might even be dangerous.

I don't think I ever was in humidity that low. Is that normal over your way?

<10%-12% is common.

I looked up once and consensus was that 40%-55% was optimal for humans.

We used to get decent monsoon season where is rained a bit each day, but in recent years it's been less and less.

I blame all you guys for driving environmentally unfriendly vehicles

Sent from my SM-G920P using Tapatalk

Mario

Active member

- 325

- 89

- 28

- Location

- Rio Rancho, NM

I just installed a Mastercool swamp cooler in my garage since I'm using it (garage) more and more since getting the humvee.It was nice when it was under 10 when I lived in Cali desert. Swamp cooler worked great when it was that dry and helped keep my bloody noses to a minimum at home

Sent from my SM-G920P using Tapatalk

Last edited by a moderator:

Jakob1944

New member

- 314

- 10

- 0

- Location

- Copperas Cove / Texas

- 18,629

- 6,298

- 113

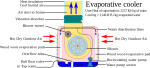

For those here who have never heard of a "SWAMP COOLER", here's a WIKI for your educational pleasure....I just installed a Mastercool swamp cooler in my garage since I'm using it (garage) more and more since getting the humvee.

Sent from my SM-G920P using Tapatalk

Officially, they are "evaporative coolers".....

https://en.wikipedia.org/wiki/Evaporative_cooler

Wire Fox

Well-known member

- 1,252

- 162

- 63

- Location

- Indianapolis, Indiana

Our office is at 7-8% humidity during the winter. So. Much. Paper. At least in the summer, there's enough Indiana humidity that seeps in from outside that we get to enjoy being at 25-30%.6% humidity?!

That sounds so low like it might even be dangerous.

I don't think I ever was in humidity that low. Is that normal over your way?

I get my fill of humidity when I'm out working on the HMMWV. Today was not an exception. Started the day with a cup of coffee and some music, just sitting in the cab and thinking about what I was going to do. When the coffee ran out, I went to grabbing all the wires I had cut and got to separating them, then started clustering them up and zip-tying them to what I believed would be the harness assembly. I spent most of the day fishing these through and fiddling with getting the lay just right. At this point, I also marked where the harness would need to branch and where splices would take place. I now also know what sizes to order for my wire loom, so this will be nice getting to move forward!

Unfortunately, I also had to note mistakes. One of the wires was copied off the wrong wire, so it was several feet short. Another wire was the victim of having been routed wrong when I was measuring, so it came to be about 4" short. I also had an improvement plan once I had everything laid out, so it will make having to order a second spool feel less wasteful. This will also be a good chance to just make reverse light wiring part of my harness, so I'll run it all at the same time. I just need to make sure that I have enough prestolite bullet connectors around for everything...

Also, I made a mistake in an earlier post regarding wire type. I really don't know where and why I believed that my 18 AWG wire needed fiberglass insulation over the teflon base... I feel like I saw it somewhere for the transmission, but can't remember where. Based off the TCM stub, it's just silver-plated, stranded copper wire in a Teflon jacket. That's much cheaper and easier to find than the ritzy stuff I mentioned, but both will work just fine!

Still didn't want to call it a day, but I was done playing with wires. I worked on cranking the engine and getting it started....really difficult to start and I'm not sure why-glow plug systems seems like it was operating optimally. Once I did get it started, it was happy to stop and start as much as I wanted it to. I decided to get out the STE-ICE kit to see if I could find anything useful. After playing around for a couple hours, I didn't find anything that was clearly at-fault. I did find my idle was set too high, so I tried to set it for the 700 RPM called for in a 6.5, but that actually caused stalling issues when I would be at high RPM and just let go of the gas. I reset to 715 and the problem was gone (dips to about 340, but doesn't hesitate or run rough for that second it's low).

You guys can also see an interesting number on the voltage test image I posted. When off, rotation switch in engine off, the starter solenoid has a slight voltage potential that's reverse polarity on the starter solenoid. I've also been noticing that my front battery keeps getting off-balanced from rear battery by dropping voltage faster. Just to eliminate all variables, I'll have to disconnect my PDU w/solar panel to ensure that it isn't causing the voltage, although the battery balance was still an issue prior to that installation.

Attachments

-

114.6 KB Views: 39

-

89.5 KB Views: 34

-

114.5 KB Views: 37

-

38 KB Views: 36

-

38.9 KB Views: 42

-

79.6 KB Views: 42

-

58.1 KB Views: 41

General Hood

Member

- 712

- 2

- 18

- Location

- Fort Towson, OK

Wire Fox

Well-known member

- 1,252

- 162

- 63

- Location

- Indianapolis, Indiana

That one's critical! That's your main connector to your PCB/EESS/S3 control box. You're at really high risk of that coming loose and causing damage to that box (notorious for getting killed just by unplugging/plugging in that connector with the vehicle off), which will be $300-600 to replace. I'd suggest deadlining the truck until you can replace the connector. Disconnect the negative battery terminal as a precaution before you mess with the connector any more. More details to follow...Raised the hood on my older M998 and noticed the electrical connection next to the windshield washer reservoir is dilapidating . I'm looking for suggestions? For now I'm going to clean it up and put a worm clamp around it to keep it in place

View attachment 688260

Another Ahab

Well-known member

- 18,129

- 4,905

- 113

- Location

- Alexandria, VA

I'm getting the picture that the high desert territory in NM ("the real midwest"), is one of those paradise places, sort of like HI.High desert here in New Mexico.

<10%-12% is common.

I looked up once and consensus was that 40%-55% was optimal for humans.

Sounds pretty nice.

- 5,759

- 3,175

- 113

- Location

- Metairie/La (N'awlins)

Is that the military diagnostic system STE ? One I had seen on flea bay looked like completely different. Please tell moreOur office is at 7-8% humidity during the winter. So. Much. Paper. At least in the summer, there's enough Indiana humidity that seeps in from outside that we get to enjoy being at 25-30%.

I get my fill of humidity when I'm out working on the HMMWV. Today was not an exception. Started the day with a cup of coffee and some music, just sitting in the cab and thinking about what I was going to do. When the coffee ran out, I went to grabbing all the wires I had cut and got to separating them, then started clustering them up and zip-tying them to what I believed would be the harness assembly. I spent most of the day fishing these through and fiddling with getting the lay just right. At this point, I also marked where the harness would need to branch and where splices would take place. I now also know what sizes to order for my wire loom, so this will be nice getting to move forward!

Unfortunately, I also had to note mistakes. One of the wires was copied off the wrong wire, so it was several feet short. Another wire was the victim of having been routed wrong when I was measuring, so it came to be about 4" short. I also had an improvement plan once I had everything laid out, so it will make having to order a second spool feel less wasteful. This will also be a good chance to just make reverse light wiring part of my harness, so I'll run it all at the same time. I just need to make sure that I have enough prestolite bullet connectors around for everything...

Also, I made a mistake in an earlier post regarding wire type. I really don't know where and why I believed that my 18 AWG wire needed fiberglass insulation over the teflon base... I feel like I saw it somewhere for the transmission, but can't remember where. Based off the TCM stub, it's just silver-plated, stranded copper wire in a Teflon jacket. That's much cheaper and easier to find than the ritzy stuff I mentioned, but both will work just fine!

Still didn't want to call it a day, but I was done playing with wires. I worked on cranking the engine and getting it started....really difficult to start and I'm not sure why-glow plug systems seems like it was operating optimally. Once I did get it started, it was happy to stop and start as much as I wanted it to. I decided to get out the STE-ICE kit to see if I could find anything useful. After playing around for a couple hours, I didn't find anything that was clearly at-fault. I did find my idle was set too high, so I tried to set it for the 700 RPM called for in a 6.5, but that actually caused stalling issues when I would be at high RPM and just let go of the gas. I reset to 715 and the problem was gone (dips to about 340, but doesn't hesitate or run rough for that second it's low).

You guys can also see an interesting number on the voltage test image I posted. When off, rotation switch in engine off, the starter solenoid has a slight voltage potential that's reverse polarity on the starter solenoid. I've also been noticing that my front battery keeps getting off-balanced from rear battery by dropping voltage faster. Just to eliminate all variables, I'll have to disconnect my PDU w/solar panel to ensure that it isn't causing the voltage, although the battery balance was still an issue prior to that installation.

Wire Fox

Well-known member

- 1,252

- 162

- 63

- Location

- Indianapolis, Indiana

Raised the hood on my older M998 and noticed the electrical connection next to the windshield washer reservoir is dilapidating . I'm looking for suggestions? For now I'm going to clean it up and put a worm clamp around it to keep it in place

View attachment 688260

Alright, I was doing some looking around. I think you've basically got two options here: replace the entire engine wiring harness (~$200 used, $450 new), or purchase a damaged wiring harness to salvage the connector off of it (~$50; you could actually purchase just the damaged part, but you'd have to identify what model series of connector that's installed, then someone can hit up a reference manual to see the exact P/N of the bayonet locking ring). If you go with the latter option, you'll have to do some wire splicing, which should be easy enough with a pack of adhesive-lined heatshrink butt splice connectors, a quality crimping tool, and a heat gun. Before going to the trouble of splicing in a connector, do yourself a favor and really look at the condition of the other connectors and the wire of the harness as best as you can. If a lot of connectors are on the way out...just replace the engine harness, as it will be cheaper in the long run.That one's critical! That's your main connector to your PCB/EESS/S3 control box. You're at really high risk of that coming loose and causing damage to that box (notorious for getting killed just by unplugging/plugging in that connector with the vehicle off), which will be $300-600 to replace. I'd suggest deadlining the truck until you can replace the connector. Disconnect the negative battery terminal as a precaution before you mess with the connector any more. More details to follow...

General Hood

Member

- 712

- 2

- 18

- Location

- Fort Towson, OK

Ugh not good. ThanksThat one's critical! That's your main connector to your PCB/EESS/S3 control box. You're at really high risk of that coming loose and causing damage to that box (notorious for getting killed just by unplugging/plugging in that connector with the vehicle off), which will be $300-600 to replace. I'd suggest deadlining the truck until you can replace the connector. Disconnect the negative battery terminal as a precaution before you mess with the connector any more. More details to follow...

Wire Fox

Well-known member

- 1,252

- 162

- 63

- Location

- Indianapolis, Indiana

Mine is the Miltope MSD STE-ICE Kit v2. All of the Miltope-type kits should be very similar with only minor revisions. The old school method is the STE/ICE-R box, which is a standalone box that you punch in what test number you want to run, hook up the correct cables, then start the test and get the results off the display. It's nice with how all-in-one it is, but I think it's a bit clunky and not as versatile as a full computer-controlled system that can functions with step-by-step diagnostics, or you can use other applications to have some more sophisticated diagnostics for a few non-military systems (obviously not the STE-ICE interface itself, but the test probes, transducers, and the DPA are near-universal).Is that the military diagnostic system STE ? One I had seen on flea bay looked like completely different. Please tell more

What's really going to jump out as different with my setup is I'm using a non-military computer to run the software I need. I'm just using some Dell laptop that was old enough to still have a serial port. I did a write-up somewhere around here about how to successfully install the included software (short ver: start with a 32-bit windows xp or 32-bit windows 7; skip the 1st disc; manually install the drivers on the 2nd disc by navigating to each sub-set and running the installer from each folder; DO NOT run the autorun installer in the first folder of the disc!).

General Hood

Member

- 712

- 2

- 18

- Location

- Fort Towson, OK

Plus the cost of the control box should it go south on me once the connector is pulled and re-connectedAlright, I was doing some looking around. I think you've basically got two options here: replace the entire engine wiring harness (~$200 used, $450 new), or purchase a damaged wiring harness to salvage the connector off of it (~$50; you could actually purchase just the damaged part, but you'd have to identify what model series of connector that's installed, then someone can hit up a reference manual to see the exact P/N of the bayonet locking ring). If you go with the latter option, you'll have to do some wire splicing, which should be easy enough with a pack of adhesive-lined heatshrink butt splice connectors, a quality crimping tool, and a heat gun. Before going to the trouble of splicing in a connector, do yourself a favor and really look at the condition of the other connectors and the wire of the harness as best as you can. If a lot of connectors are on the way out...just replace the engine harness, as it will be cheaper in the long run.

FKAM

Active member

- 138

- 64

- 28

- Location

- Duchesne, Utah

I decided to get out the STE-ICE kit.....

Like Juan, would like to hear more about your STE-ICE kit. I've been trying to figure out how to get/make one for use on the HMMWV.Is that the military diagnostic system STE ? One I had seen on flea bay looked like completely different. Please tell more

General Hood

Member

- 712

- 2

- 18

- Location

- Fort Towson, OK

Thank you for the advise WF, I spent last summer re-wiring a FLU419 (a daunting task which expanded my vocabulary considerably) so it looks like I'm in for another treatAlright, I was doing some looking around. I think you've basically got two options here: replace the entire engine wiring harness (~$200 used, $450 new), or purchase a damaged wiring harness to salvage the connector off of it (~$50; you could actually purchase just the damaged part, but you'd have to identify what model series of connector that's installed, then someone can hit up a reference manual to see the exact P/N of the bayonet locking ring). If you go with the latter option, you'll have to do some wire splicing, which should be easy enough with a pack of adhesive-lined heatshrink butt splice connectors, a quality crimping tool, and a heat gun. Before going to the trouble of splicing in a connector, do yourself a favor and really look at the condition of the other connectors and the wire of the harness as best as you can. If a lot of connectors are on the way out...just replace the engine harness, as it will be cheaper in the long run.

- 5,759

- 3,175

- 113

- Location

- Metairie/La (N'awlins)

I have some ends that were cut off with maybe 4-6 inches of wire with some spare boxes I picked up so If you need an end ......Plus the cost of the control box should it go south on me once the connector is pulled and re-connected

- 114,117members

- 167,077threads

- 2,352,297posts

- 3,131online users