Crapgame

Well-known member

- 642

- 342

- 63

- Location

- Navarre, FL

Replaced Battery Cables: Short in Negative SubHarness to Starter & Engine

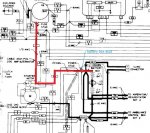

Edit: The buyer stopped by yesterday to test drive it again, and we found the electrical problem by accident. After I had checked the voltage on the starter switch I guess I crossed the two hot Packard connectors. Kevin was under the battery box tracing the sub harness assembly of black nylon mesh sheathed cables, about 4 ea 16ga black wires that enters the battery box from transmission hump, below the STC/IC Shunt, when the starter began cranking the engine by itself.

Apparently, when I moved the red 1/0 cable to the alternator lug over top the shunt and bolted it back onto the insulated Positive anchor point, that somehow I may have rotated the positive anchor point, maybe some aluminum oxide build up was causing some voltage loss, or wear on that 4 wire sub bundle to the starter to the engine developed some kind of short.

So it looks like I should replace the A0 engine harness or at least that sub assembly to the starter then goes under the air horn over top the engine then splits at a T under the transmission cover.

I knew it would be something stupid simple, but invisible to me due to pain-inflicted tunnel vision.

My 1987 A0 truck came with 2 Walmart 12v batteries bungied to the battery box floor. I removed the bungees, pop riveted two L brackets with holes to use aftermarket J bolts/wing nuts and the GI battery hold down, but the GI hold down would fit right with the civilian batteries. I made a new, longer 2/0 cable to connect the two Walmart batteries to work with the GI hold down but it still wasn't enough room. So I cut two pieces of 1" wide 0.125" thick aluminum flat bar with holes in the ends to work with the J bolts and wing nuts. I started the truck and ran it for awhile before final installation of the improvised hold down parts.

But once I installed the aluminum flat bars across the battery handles, etc, I got the Wait and Brake lights on for about half a second then they went out, no power to the starter switch now. Two 1" flat bars like on the right battery in the above photo.

Did I toast the glow plug controller with an arc in the battery compartment?

I tried manipulating the gear shifter to make sure the Neutral switch wasn't off but no lights still.

I'm getting 24v on the multimeter touching the - terminal and the red marked shunt bolts on the battery box side

Edit: The buyer stopped by yesterday to test drive it again, and we found the electrical problem by accident. After I had checked the voltage on the starter switch I guess I crossed the two hot Packard connectors. Kevin was under the battery box tracing the sub harness assembly of black nylon mesh sheathed cables, about 4 ea 16ga black wires that enters the battery box from transmission hump, below the STC/IC Shunt, when the starter began cranking the engine by itself.

Apparently, when I moved the red 1/0 cable to the alternator lug over top the shunt and bolted it back onto the insulated Positive anchor point, that somehow I may have rotated the positive anchor point, maybe some aluminum oxide build up was causing some voltage loss, or wear on that 4 wire sub bundle to the starter to the engine developed some kind of short.

So it looks like I should replace the A0 engine harness or at least that sub assembly to the starter then goes under the air horn over top the engine then splits at a T under the transmission cover.

I knew it would be something stupid simple, but invisible to me due to pain-inflicted tunnel vision.

My 1987 A0 truck came with 2 Walmart 12v batteries bungied to the battery box floor. I removed the bungees, pop riveted two L brackets with holes to use aftermarket J bolts/wing nuts and the GI battery hold down, but the GI hold down would fit right with the civilian batteries. I made a new, longer 2/0 cable to connect the two Walmart batteries to work with the GI hold down but it still wasn't enough room. So I cut two pieces of 1" wide 0.125" thick aluminum flat bar with holes in the ends to work with the J bolts and wing nuts. I started the truck and ran it for awhile before final installation of the improvised hold down parts.

But once I installed the aluminum flat bars across the battery handles, etc, I got the Wait and Brake lights on for about half a second then they went out, no power to the starter switch now. Two 1" flat bars like on the right battery in the above photo.

Did I toast the glow plug controller with an arc in the battery compartment?

I tried manipulating the gear shifter to make sure the Neutral switch wasn't off but no lights still.

I'm getting 24v on the multimeter touching the - terminal and the red marked shunt bolts on the battery box side

Last edited: