- 1,308

- 1,677

- 113

- Location

- Basehor, KS

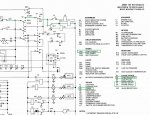

Kris,

this would be your modified wiring diagram:

S2A = 3 Pole 2 Position DPDT maintained action

S2B = 2 Pole 2 Position DPDT momentary action

this would be your modified wiring diagram:

S2A = 3 Pole 2 Position DPDT maintained action

S2B = 2 Pole 2 Position DPDT momentary action

Since I have very limited understanding of electrical schematics, I was wondering if anyone figured out the function of each wire during stop run and start positions.

I think maybe I can if I knew, figure things out using marine grade switches. Yall already said no but I'm stubborn.