- 18,063

- 27,094

- 113

- Location

- Burgkunstadt, Germany

Update,

uninstalling the float was a back breaker and half of the screws you cant see.

You have to use a stubby flat head screw driver because of the confined area vertically.

Would have been better if the screws were hex head.

Went thru Guys instruction's for the test. No Bueno. Fuel gage said full no matter what the position the float was in.

Then Peter said it was totally mechanical and a easy fix.

Since it is mechanical I commenced to disassemble it. Peter was correct that it can be fixed.

I found corrosion on the surfaces and the surfaces were crusty. One surface cleaned up with scotch bright and the other had to be sanded.

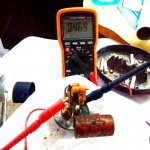

After that Peter gave me instructions to test with an OHM meter. I did this before and after the fix. Before the readings were not good at all, no continuity on some positions. He blessed it with a meter reading of 46.9 ohms in the full position and 8.7 ohms in the empty position after fix.

So next I will reinstall the float and test to Guys test procedure. The test procedure is definitely a two person job.

I sent Peter some pics of the float disassembled and he said he would post it here and enhance them.

Kris

Well, I could have told you its a PITA. But didn't want to give you a reason to put it off until the second coming.

You are becoming a first class generator mech!

So put some hex head screws back in it!

Peter gave you instructions that came straight out of the TM. Never hurts to look in them before doing anything you have never done before.

You are lookin good!