Ordered a 6.2 flywheel to compare to a stock 6.5, since the 6.2 is heavier I'm wondering if it's thicker..

In the meantime I'm going to bleed my clutch and see if the current setup can actually release the clutch or not. How did you go about bleeding the slave seeing as how the bleeder screw is pointed right at the oil cooler lines...

Edit.. Clutch bled but the clutch fork hits the bell housing before the pedal bottoms out. The trick to getting it bled is to unmount the slave cylinder from the bell housing, remove the reservoir cap, crack the bleeder and let fluid just drain down until it comes out the bleeder. Then close the bleeder and pump the pushrod on the slave, forcing the air bubbles up and out (with reservoir cap removed). Eventually it gets nice and firm and you can mount it back up and you're done. Don't even need two people!

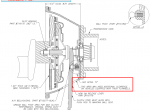

The good news is that after bleeding it does release the clutch disc before the fork hits the bell housing. After bleeding the slave, I had to use the nuts on the mounting stud to pull it onto the mount, forcing the rod all the way in even with the adjusting nuts bottomed out. This put a bit of tension on the pressure plate, perhaps too much.

It seems like I would need to clearance the back part of the bell housing for the clutch fork, which would solve the fork bottoming out before the pedal, but not do anything for the preload I have to put in to the throwout bearing just to get things mounted up.

More edit.. Went out to see where in the pedal travel the clutch disengaged to find that it would no longer do that... So I pulled the bellhousing to make sure the pressure plate was bolted down all the way and it is.. A bit lost for now, going to call Advance Adapters tomorrow and see what they have to say.