Cave Johnson

Member

- 35

- 84

- 18

- Location

- Texas

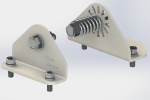

Anyone else lacking the the upper and lower mirror brackets? (lower shown below). My truck only came with the driver side mirror assembly, so Im replicating it for the passenger end.

Im going to have a set burned out for myself, but I wouldnt mind having more made to dilute the setup cost. (Example, lower bracket one unit will cost about 50, 2 units 35 each, 3 units 30 each, logarithmic decline to 20 each)

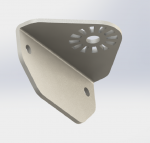

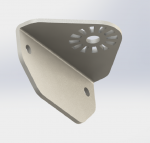

I know the actual unit has those dimples pressed in, but cutting them out should function identically, my model shown below.

Im going to have a set burned out for myself, but I wouldnt mind having more made to dilute the setup cost. (Example, lower bracket one unit will cost about 50, 2 units 35 each, 3 units 30 each, logarithmic decline to 20 each)

I know the actual unit has those dimples pressed in, but cutting them out should function identically, my model shown below.