Hey gang,

I've gone dark here a bit lately with a few other projects getting priority, but thanks to @Lostchain, I recently took a run at troubleshooting the CTIS issue I had in the fall. For those late to the party, I documented it here:

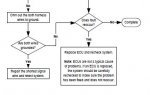

Long story short, we found a very obvious leak where the RT front line was disconnected from the valve. Ever so optimistically, I started up the system again and it still didn't work. It was cycling a solenoid at about 2Hz. We went through the entire Dana procedure, checking solenoid resistances, continuities, etc... and got to the end of the troubleshooting procedure which basically said I need to replace the ECU. The codes on the Dana system were 34, 35, and 54. We fixed the 26- massive leak in system.

As part of our non-TM troubleshooting, we checked the pressure switch at the wet tank and couldn't get a reading on it from the plug. Even with it unplugged though, the system tried to work- it was cycling the solenoid. As we understand it, without a signal (closed switch) from the pressure tank, the system shouldn't be doing anything.

If the ECU is trying to run the system with an open circuit from the pressure switch, is that indicative of a bad ECU? That is about the only thing that might make sense out of this to me.

Does any of this make sense to anyone? Is there something we missed in the troubleshooting? Any recommendations? Anybody have a spare ECU (2000 M1088A1)?

Thanks in advance,

Chris

I've gone dark here a bit lately with a few other projects getting priority, but thanks to @Lostchain, I recently took a run at troubleshooting the CTIS issue I had in the fall. For those late to the party, I documented it here:

Help needed/truck stuck - Cycling pneumatic relay under PDP in 2000 M1088 w/3126

Need some help from the forum's collective knowledge.... Took my truck ~100 miles yesterday to Eugene to have the habitat structure blasted and painted. Drive down was hot with a bit of traffic but went smoothly. The fan cycled a bit more than expected but ran everything ran fine despite my...

www.steelsoldiers.com

Long story short, we found a very obvious leak where the RT front line was disconnected from the valve. Ever so optimistically, I started up the system again and it still didn't work. It was cycling a solenoid at about 2Hz. We went through the entire Dana procedure, checking solenoid resistances, continuities, etc... and got to the end of the troubleshooting procedure which basically said I need to replace the ECU. The codes on the Dana system were 34, 35, and 54. We fixed the 26- massive leak in system.

- Code 34:

NO PCU SENSOR READING (System non-operative): No sensor voltage to ECU. Clears 5 seconds following a valid reading. 1) Sensor is electrically disconnected 2) Pressure signal wire (XDCR SIGNAL) is shorted to ground, or open 3) PCU sensor VREF wire is shorted to ground, or open 4) Faulty sensor PCU SENSOR READING TOO HIGH (System non-operative): Sensor voltage higher than allowed. Clears 5 seconds following a valid reading. 1) Pressure signal wire (XDCR SIGNAL) is shorted to power or XDCR VREF 2) Faulty sensor

- Code 35:

OUT OF RANGE ATMOSPHERIC READING (System waits to check pressures): Atmospheric pressure check indicates vented PCU pressure is outside of valid atmospheric range (5-20 psia). Repair and request pressure check to clear (press any mode button or run flat). 1) Poor ground connection to PCU sensor 2) Faulty PCU sensor (ex, frozen water contamination) 3) Faulty PCU or blocked PCU exhaust vent

- Code 54:

ELECTRICAL SOLENOID FAILURE (System non-operative): Solenoid fails electrical diagnostics for approximately 2 seconds. Repair & cycle ignition to clear. 1) Solenoid or harness wire is shorted to ground 2) Solenoid or harness wire is shorted to power 3) Faulty solenoid

As part of our non-TM troubleshooting, we checked the pressure switch at the wet tank and couldn't get a reading on it from the plug. Even with it unplugged though, the system tried to work- it was cycling the solenoid. As we understand it, without a signal (closed switch) from the pressure tank, the system shouldn't be doing anything.

If the ECU is trying to run the system with an open circuit from the pressure switch, is that indicative of a bad ECU? That is about the only thing that might make sense out of this to me.

Does any of this make sense to anyone? Is there something we missed in the troubleshooting? Any recommendations? Anybody have a spare ECU (2000 M1088A1)?

Thanks in advance,

Chris