Crazyls2

Active member

- 83

- 179

- 33

- Location

- Charleston SC

Before I get web attacked from 100 different people, I attempted to find the information in old posts and the TM.....

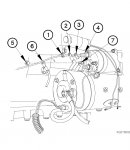

My LMTV had the starter rebuilt the week I brought it home. It has given me fits since I got it. I chased an electrical issue a few months ago only to figure out if I smacked the starter with a hammer it would start. I would need to do that from time to time especially if I let it sit for a month or more. My alternator craped out on me 6 months ago so it's been sitting. I finally got around to having the alternator rebuilt and when I put everything back on the truck just makes a clicking sound when I try and turn it over. I beat the hell out of the starter thinking that was my problem but it never made any difference. Yesterday I pulled the starter and brought it home with the intention of finding someone to rebuild it. After going through the TM i am wondering if I gave a secondary solenoid problem.

Is there a way to hook the starter up to batteries while it's off the truck and try testing it? I put 24v to it this afternoon thinking if I jumped the two smaller lugs it would spin over but it didn't. Must I have the other solenoid to get it to spin over? If not, can someone tell me how to test it?

My LMTV had the starter rebuilt the week I brought it home. It has given me fits since I got it. I chased an electrical issue a few months ago only to figure out if I smacked the starter with a hammer it would start. I would need to do that from time to time especially if I let it sit for a month or more. My alternator craped out on me 6 months ago so it's been sitting. I finally got around to having the alternator rebuilt and when I put everything back on the truck just makes a clicking sound when I try and turn it over. I beat the hell out of the starter thinking that was my problem but it never made any difference. Yesterday I pulled the starter and brought it home with the intention of finding someone to rebuild it. After going through the TM i am wondering if I gave a secondary solenoid problem.

Is there a way to hook the starter up to batteries while it's off the truck and try testing it? I put 24v to it this afternoon thinking if I jumped the two smaller lugs it would spin over but it didn't. Must I have the other solenoid to get it to spin over? If not, can someone tell me how to test it?

Attachments

-

5.8 MB Views: 18