- 147

- 282

- 63

- Location

- NC

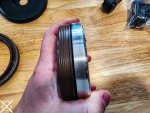

While I'm waiting on parts from Allison, I figured I would tackle the corner bolt issue which was so, so much worse than I thought it was haha. When I removed this shorter, yellow zinc coated bolt... A section of aluminum threads came out with it.

As seen here, with an original transmission bolt which is ~5-10mm longer. Some eagle eyed members might also notice another issue...

The bolt in the trans that ripped the threads out is actually an SAE bolt cranked in to an M10x1.5 hole.

In addition to some higher up threads being broken, the lower threads were all buggered up:

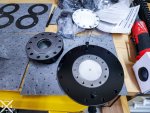

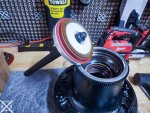

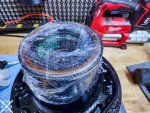

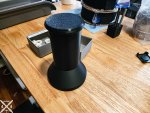

After some internet research, I bought this M10x1.5 Helicoil kit, the shortest 13/32 bit I could find, and the shortest 90* adapter I could find. The 90* adapter was for "impact" but there wasn't much slop so I figured I'd give it a try. Ended up working.

The tap and installation tool were too long so I 3d printed some softjaws, cut them down, and squared the ends to fit snugly in a ratcheting box wrench:

I haven't used too many helicoils before, but seemed to go more or less according to plan. Trying to figure out the best plan for helping those gouges and scrape marks seal... he worst ones are perhaps 1/32" deep or less than 1mm. I think there are two of them, from where someone pried on the aluminum trans block to separate rather than using the jacking ports. Thinking of adding a small amount of RTV on both sides of a new gasket from Allison. Thoughts ? Other recommendations ?

As seen here, with an original transmission bolt which is ~5-10mm longer. Some eagle eyed members might also notice another issue...

The bolt in the trans that ripped the threads out is actually an SAE bolt cranked in to an M10x1.5 hole.

In addition to some higher up threads being broken, the lower threads were all buggered up:

After some internet research, I bought this M10x1.5 Helicoil kit, the shortest 13/32 bit I could find, and the shortest 90* adapter I could find. The 90* adapter was for "impact" but there wasn't much slop so I figured I'd give it a try. Ended up working.

The tap and installation tool were too long so I 3d printed some softjaws, cut them down, and squared the ends to fit snugly in a ratcheting box wrench:

I haven't used too many helicoils before, but seemed to go more or less according to plan. Trying to figure out the best plan for helping those gouges and scrape marks seal... he worst ones are perhaps 1/32" deep or less than 1mm. I think there are two of them, from where someone pried on the aluminum trans block to separate rather than using the jacking ports. Thinking of adding a small amount of RTV on both sides of a new gasket from Allison. Thoughts ? Other recommendations ?