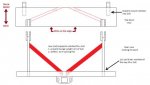

Mudguppy, check the labels this pic. describing location of the angled bracing on the 2x6. I get what you are saying about the tounge weight twisting, that is why I was going to attach the bottom of the angled supports to the top edge of the 2x6 on the side opposite the receiver. This is what you are saying right? Which is the top/rear edge you were mentioning? ...

no - the other way around. mount the diagonals on the rearward edge, closest to the reciever opening (and thus the tongue weight).

it does seem logical that the diagonals attached at the front edge of the 2x6 would prevent the tiwist. however, these would do very little to combat vertical forces (tongue weight) from bending the 2x6 downward. and when it does bend downward, it will twist because of the diagonals holding the front 2x6 edge in place.

if you mount the diagonals on the rear edge (closest to the reciever), they will actually bear nearly the entire vertical load (tongue weight). this also minimizes the moment arm that the tongue weight will have to act on twisting the 2x6; and a 2x6 will resist end-encapsulated twisting (torsional deflection) much better than it can resist linear deflection across it's minor axis (bending downward across the 2" dimension).

you're just beefing the vulnerable areas and letting the positive attributes fend for themselves.

and as for the rest of the speculations in this thread; remember, that's exactly what they are (mine included, more like '

especially'). who the crap do you think is going to 'inspect' the deuce frame and be able to determine which hole is 'authorized' and which is not, let alone

cite you for it.

liability?

you'd have to

rate it in order for

you to be liable. no rating = user discretion and responsibility. rate it for x,000 lbs and you just created a certain threshold of liability - if it fails while performing under that rating, it could your fault as the 'manufacturer'.

actually, what i'd do is put a "

For Offroad use ONLY" sticker on it if i sold them.

![receiver%20suppot[1].jpg](/data/attachments/162/162224-8b12022e06b7d0ef975355237ec0fd3f.jpg)