John Mc

Well-known member

- 253

- 365

- 63

- Location

- Monkton, VT

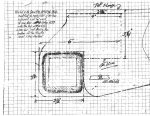

I'm looking to add a 2" receiver hitch on my 1951 M37. I want to keep the stock pintle hitch. I've seen a few pictures of people who fabricated a receiver set up. I'm thinking of mounting a stock aftermarket receiver hitch sold for modern trucks. It seems the frame rail spacing is the same as modern trucks. On another site, a member mounted a hitch he removed off his 2001 Dodge Ram onto his M37. All that was required was drilling the mounting holes in the frame. His hitch had a LOT of drop (necessary to clear the bumper on his modern truck). It caused him to lose more ground clearance than necessary.

I'm looking to find a manufactured hitch that will fit as close as possible under the frame without interfering with the pintle hitch. I'm open to other options, but I don't want to lose the pintle hitch (I dont currently own any pintle hitch trailers, but I like the look, and may own one in the future). I'm concerned about mounting something on the cross member, particularly because the large drop required to get the ball to the proper height (I have 11.00x16 tires) seems as though it would put quite a twisting moment on the cross member when towing. A frame mounted hitch avoids this concern.

Since none of the online trailer hitch places I've checked have any dimensional information online, I'll be making a visit to a local hitch sales/installation place to see what they may have. Since I doubt many places have a huge inventory of hitches waiting to install that we can just hold up for a test fit, I'm hoping someone here has already done this, and has a recommendation for an make/model of an aftermarket, frame mounted hitch that makes for a good fit on an M37. Appearance-wise, I'd prefer a "squared-off" look; I think that would make a better fit with the character of the truck, rather than a hitch made from round or bent tubing.

So has anyone done this? Any leads would certainly shorten my search process.

I'm looking to find a manufactured hitch that will fit as close as possible under the frame without interfering with the pintle hitch. I'm open to other options, but I don't want to lose the pintle hitch (I dont currently own any pintle hitch trailers, but I like the look, and may own one in the future). I'm concerned about mounting something on the cross member, particularly because the large drop required to get the ball to the proper height (I have 11.00x16 tires) seems as though it would put quite a twisting moment on the cross member when towing. A frame mounted hitch avoids this concern.

Since none of the online trailer hitch places I've checked have any dimensional information online, I'll be making a visit to a local hitch sales/installation place to see what they may have. Since I doubt many places have a huge inventory of hitches waiting to install that we can just hold up for a test fit, I'm hoping someone here has already done this, and has a recommendation for an make/model of an aftermarket, frame mounted hitch that makes for a good fit on an M37. Appearance-wise, I'd prefer a "squared-off" look; I think that would make a better fit with the character of the truck, rather than a hitch made from round or bent tubing.

So has anyone done this? Any leads would certainly shorten my search process.