rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

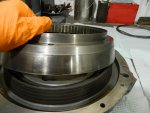

There are differences between civilian and military units. The front pump is "not" one of them though. All HydraMatics came with the 7 vane front pump. That being said there is a surprise I'm going to post here later.

The rear pump is the same also except for the line going to the reduction unit. So it has a different housing.

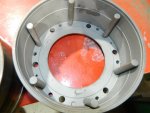

Also the "main" housing is very different as you can see here. The left housing is a Pontiac and the right is the 303M housing.

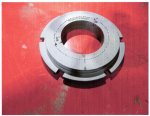

A major difference is in the 2 main clutches. The pistons use a solid seal ring instead of a rubber "lip seal".

I can only guess the military wanted no possibility of clutch failure due to overheat melting the lip seal or the lip seal leaking due to a tear caused by debris in the fluid or pieces of friction material causing a tear.

This means you cannot use rubber lip seals on these units without some machine work.

Also, all military units came with a 4-pinion planetary instead of the standard 3-pinion planetary.

About the crack. No it cannot be safely welded up. It is in a high stress area and would only crack again.

I can say this due to the fact I was a welder for 10 years and cast iron was one of the metals I welded on a regular basis. That and Aluminum and Stainless Steel. I did weld "black Iron" , but that work was usually welded by another Welder who did nothing but weld "Black Iron" all day long. I at least got a break and could play with other metals.

About running in "high reverse" . High gear in the reduction is nothing more than a 1:1 output. So basically it means your running a "Normal" transmission or from Military's point of view, your running the "301MG" transmission.

The reduction unit just has 2 ratio outputs. Low and High, (high meaning a regular 1:1 output) .

Now there is a problem with all HydraMatic transmissions. They have excessive internal leakage, so the oil pumps must work very hard in normal conditions to keep up with the "normal" loss of pressure. That is one reason the 303M transmission has 2 functional oil pumps. The front pump, and the reduction units rear pump. The main housing rear pump does nothing but help drain the reduction unit and of course it holds the "governor" . The fluid from this pump is just squirted out of the housing.

Having three pumps is one of the reasons this transmission runs so hot and needs that oil cooler. All fluid once it is pressurized gets hot from that process. Air does the same thing. Ever touch the return line on your air compressor after it has just run ? It will burn your hand. Oil does the same thing.

These issues of leaking were addressed in later HydraMatics. The use of "rubber seals" in ALL clutches for one, and better sealing "seal rings" for another.

The rear pump is the same also except for the line going to the reduction unit. So it has a different housing.

Also the "main" housing is very different as you can see here. The left housing is a Pontiac and the right is the 303M housing.

A major difference is in the 2 main clutches. The pistons use a solid seal ring instead of a rubber "lip seal".

I can only guess the military wanted no possibility of clutch failure due to overheat melting the lip seal or the lip seal leaking due to a tear caused by debris in the fluid or pieces of friction material causing a tear.

This means you cannot use rubber lip seals on these units without some machine work.

Also, all military units came with a 4-pinion planetary instead of the standard 3-pinion planetary.

About the crack. No it cannot be safely welded up. It is in a high stress area and would only crack again.

I can say this due to the fact I was a welder for 10 years and cast iron was one of the metals I welded on a regular basis. That and Aluminum and Stainless Steel. I did weld "black Iron" , but that work was usually welded by another Welder who did nothing but weld "Black Iron" all day long. I at least got a break and could play with other metals.

About running in "high reverse" . High gear in the reduction is nothing more than a 1:1 output. So basically it means your running a "Normal" transmission or from Military's point of view, your running the "301MG" transmission.

The reduction unit just has 2 ratio outputs. Low and High, (high meaning a regular 1:1 output) .

Now there is a problem with all HydraMatic transmissions. They have excessive internal leakage, so the oil pumps must work very hard in normal conditions to keep up with the "normal" loss of pressure. That is one reason the 303M transmission has 2 functional oil pumps. The front pump, and the reduction units rear pump. The main housing rear pump does nothing but help drain the reduction unit and of course it holds the "governor" . The fluid from this pump is just squirted out of the housing.

Having three pumps is one of the reasons this transmission runs so hot and needs that oil cooler. All fluid once it is pressurized gets hot from that process. Air does the same thing. Ever touch the return line on your air compressor after it has just run ? It will burn your hand. Oil does the same thing.

These issues of leaking were addressed in later HydraMatics. The use of "rubber seals" in ALL clutches for one, and better sealing "seal rings" for another.

Last edited: