Csm Davis

Well-known member

- 4,169

- 406

- 83

- Location

- Hattiesburg, Mississippi

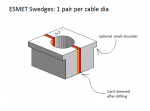

Yeah I have worked with the Engineers from Sampson and Esmet on a setup for the 5 ton wreckers and it is much stronger than the stock setupBreaking strength on the stock 6x19 fiber core cable is 20-22k pounds. Working load is lower figuring either a 3, 4, or 5 :1 WLL. I'm going to synthetic on mine (yes it's approved for cranes, even available direct from the manufacturer with synthetic for the past few years) with a breaking strength of 27k.

Sent from my SM-G930V using Tapatalk