You know I swore that I would never do a half job again on engines some time ago. I recently made and exception on my 95 Ford F150 and did the lower bearings while the tranny was out but the engine still in the vehicle. But I was told less than a year before that, that the upper was in great shape by a mechanic that has been working on my cars for some time now.

Here I am faced with the fact that the engine was rebuilt recently, torn down, built again, then passed on to me Hard to believe that Scot would have not seen that between the builds as there were no gaskets on the valve covers. If it was not overlooked, then this is recent and got to tell you that yesterday after I worked on it some, it sounded different from days past. Almost like it was skipping, as we would say when the ole spark plug failed, in gas engines.

So if this is recent, then the problem is still going to exist. I am beginning to think that it would be unwise to stop at this point as I need parts and they are going to take a couple of days to get here so I have the time to continue down the tear down road. I have to empty the radiator anyways because I have flush in it right now and it is time to cycle it out.

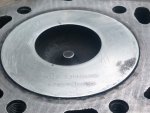

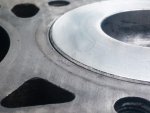

Finding this broken rocker arm may mean that there are metal chips in my enigne oil right now and that my new break in oil is not trashed along with the brand new oil filter. This means that the crankcase cover is going to have to come off so that I can get everything out of the sump. At the same time, it would give me an opportunity to readjust my oil pressure relief valve up a couple more psi. I do not think running at 22 -23 psi when warm is adequate. Maybe up it to 35 psi. It is showing about 50 psi when cold but that only last about 3 minutes.