USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Nothing wrong with my batteries. They are brand new and crank the engine just fine. This is not a battery issue.

From the tm:

With the cranking relay energized, power passes from the batteries through closed contacts of the crank-ing relay to energize the solenoid and the pulling coil of the fuel solenoid. With the solenoid energized, power passes fromthe batteries through closed contacts of the solenoid to the cranking motor. The cranking motor then cranks the engine.As the engine accelerates to approximately 900 rpm, the magnetic pickup, which senses engine speed, causes the crankdisconnect switch to break the circuit to the coil of the crank disconnect relay and close the contacts of the field flash relay.When the MASTER SWITCH is moved to one of the RUN positions, both starting control circuits are deenergized whilethe instrument and other control circuits remain energized. The fuel solenoid holding coil remains energized.

1-12.8.1.3 The engine may be cranked without starting by use of the DEAD CRANK switch. With the DEAD CRANKswitch in the CRANK position, the cranking relay coil is energized to initiate engine cranking without energizing any otherstarting or control function.

So if K14 is not the issue, cranking relay or are they the same?

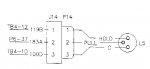

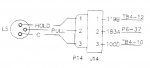

Need a friggin real schematic of the wiring.

From the tm:

With the cranking relay energized, power passes from the batteries through closed contacts of the crank-ing relay to energize the solenoid and the pulling coil of the fuel solenoid. With the solenoid energized, power passes fromthe batteries through closed contacts of the solenoid to the cranking motor. The cranking motor then cranks the engine.As the engine accelerates to approximately 900 rpm, the magnetic pickup, which senses engine speed, causes the crankdisconnect switch to break the circuit to the coil of the crank disconnect relay and close the contacts of the field flash relay.When the MASTER SWITCH is moved to one of the RUN positions, both starting control circuits are deenergized whilethe instrument and other control circuits remain energized. The fuel solenoid holding coil remains energized.

1-12.8.1.3 The engine may be cranked without starting by use of the DEAD CRANK switch. With the DEAD CRANKswitch in the CRANK position, the cranking relay coil is energized to initiate engine cranking without energizing any otherstarting or control function.

So if K14 is not the issue, cranking relay or are they the same?

Need a friggin real schematic of the wiring.