B-Dog

Well-known member

- 170

- 294

- 63

- Location

- Denver, CO

Hey all,

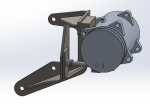

Here's a custom compressor bracket you can make. I'm not interested in making these, just thought I'd share if anyone was interested.

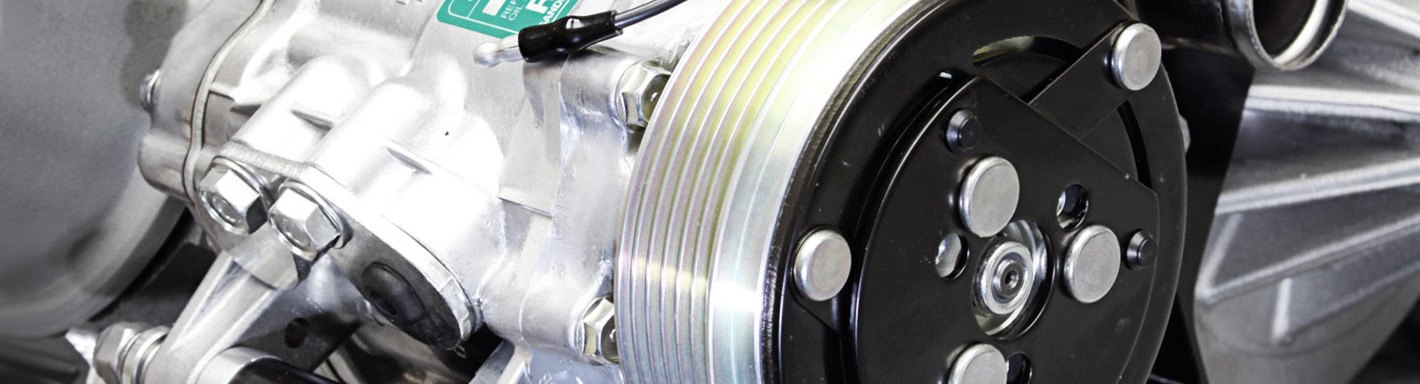

The exact dimensions and layout might have to be modified to fit your exact pulley & compressor. I used a custom pulley and a 75r8424 compressor. See attached PDF for 1:1 prints of the parts. You should be able to print those then trace them onto paper to cut out. The big part didn't fit on a letter sized paper so you'll have to print that one on 11x17 (sorry), everything else is on 8 1/2x11. Dimensions are on the parts just to make sure you printed it 1:1 scale.

I made the top bar a little short 2 3/4" to allow for adjusting the compressor (forward and backward) to align the pulleys. Use shims, as needed. I made everything out of 1/4" plate, except the blocks of course.

The swivel thing at the end of the adjuster is McMaster PN 8955A14 and that's there because the bolt changes angles.

Cheers,

Here's a custom compressor bracket you can make. I'm not interested in making these, just thought I'd share if anyone was interested.

The exact dimensions and layout might have to be modified to fit your exact pulley & compressor. I used a custom pulley and a 75r8424 compressor. See attached PDF for 1:1 prints of the parts. You should be able to print those then trace them onto paper to cut out. The big part didn't fit on a letter sized paper so you'll have to print that one on 11x17 (sorry), everything else is on 8 1/2x11. Dimensions are on the parts just to make sure you printed it 1:1 scale.

I made the top bar a little short 2 3/4" to allow for adjusting the compressor (forward and backward) to align the pulleys. Use shims, as needed. I made everything out of 1/4" plate, except the blocks of course.

The swivel thing at the end of the adjuster is McMaster PN 8955A14 and that's there because the bolt changes angles.

Cheers,

Attachments

-

119.3 KB Views: 18

-

45.1 KB Views: 7