goldneagle

Well-known member

- 4,738

- 1,509

- 113

- Location

- Slidell, LA

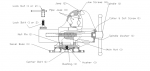

I got a good deal on a Ridgid 600PN bench vise that was installed on a M936 wrecker. I need to repair the collar that is attached to the shaft. I is loose and I cannot move the jaw out with it being loose.

Just wonder if anyone has come across one or has one. It is HUGE! Pictures to follow shortly.

Just wonder if anyone has come across one or has one. It is HUGE! Pictures to follow shortly.