-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Anyone interested in heavier duty hydraulic head button retaining clips?

- Thread starter Davidwyby

- Start date

More options

Who Replied?- 6,425

- 4,990

- 113

- Location

- Ft. Lauderdale, Florida

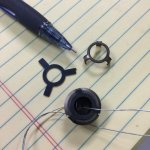

pitchers pictures photosGot test piece from waterjet, I'm liking it. Forms/bends well and is nice and strong even before heat treat. Going to have him add some more meat to the O.D. and then we'll make the forming jig.

mt4x4

Member

- 46

- 2

- 8

- Location

- Springfield, Oregon

I would take a few.

rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

Keep up the good work David !Update: Have a trial run of 10 pcs waterjet cut and need to get in the machine shop to make the bending/forming jigs, but we are overbooked for a while. Having a hard time finding good manual machinists.

- 7,426

- 2,537

- 113

- Location

- Interlachen Fl.

Hope all works well. Would be interesting if the button retainer tabs could be longer and extend under the plunger spring locking it in place instead of a friction fit. As the threads have talked about I believe the clip was designed just to hold the button on long enough to install the Head. With button/plunger installed and always in contact with the tappet it makes no sense why we loose them. Just had a thought on the wear of the button could it wear out enough to allow a gap between the it and the tappet? That meaning if the button clip falls off we need a new clip and button.

Attachments

-

54.6 KB Views: 28

Last edited:

rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

I believe it has more to do with a weak spring allowing the plunger valve to "bounce" on the piston.Hope all works well. Would be interesting if the button retainer tabs could be longer and extend under the plunger spring locking it in place instead of a friction fit. As the threads have talked about I believe the clip was designed just to hold the button on long enough to install the Head. With button/plunger installed and always in contact with the tappet it makes no sense why we loose them. Just had a thought on the wear of the button could it wear out enough to allow a gap between the it and the tappet? That meaning if the button clip falls off we need a new clip and button.

- 7,426

- 2,537

- 113

- Location

- Interlachen Fl.

Guess we will never know. Good reason to have a 5 ton or bigger I guess.

orren

Active member

- 244

- 26

- 28

- Location

- Live Oak, Florida, USA

I would like to see someone try back cutting the three notches in spring retainer; even if

things get a little too wobbly the over bend in the clip's three prongs would still hold enough

especially with these new heavy duty clips.

Comments ???

things get a little too wobbly the over bend in the clip's three prongs would still hold enough

especially with these new heavy duty clips.

Comments ???

I believe it has more to do with a weak spring allowing the plunger valve to "bounce" on the piston.

- 7,426

- 2,537

- 113

- Location

- Interlachen Fl.

Guess one could try Orren. Still think it would be easer to make the tabs longer and tuck them under the spring.

orren

Active member

- 244

- 26

- 28

- Location

- Live Oak, Florida, USA

Good idea James. But the spring action might eventually wear thru the tab. Just a thought.

Guess one could try Orren. Still think it would be easer to make the tabs longer and tuck them under the spring.

rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

I have come up with a new theory as to why we loose the clips. When the deuce is allowed to set for long periods the old diesel fuel gets gummy and causes the plunger to stick in the bore. Then when you go to start it up, the first time the plunger hits the top of it's bore it sticks and looses contact with the cam piston allowing the clip to fall off. I have found this in several of the injection pumps I tore down.Hope all works well. Would be interesting if the button retainer tabs could be longer and extend under the plunger spring locking it in place instead of a friction fit. As the threads have talked about I believe the clip was designed just to hold the button on long enough to install the Head. With button/plunger installed and always in contact with the tappet it makes no sense why we loose them. Just had a thought on the wear of the button could it wear out enough to allow a gap between the it and the tappet? That meaning if the button clip falls off we need a new clip and button.

Agree. I think that's why mine wouldn't start after sitting 20 years. I recommend soaking with kroil or whatever before startup.I have come up with a new theory as to why we loose the clips. When the deuce is allowed to set for long periods the old diesel fuel gets gummy and causes the plunger to stick in the bore. Then when you go to start it up, the first time the plunger hits the top of it's bore it sticks and looses contact with the cam piston allowing the clip to fall off. I have found this in several of the injection pumps I tore down.

But why do they sometimes fall off when the truck is being driven regularly? Debris in fuel? Chunk of filter media or even fibers maybe could wedge the plunger.

rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

That is about the only thing that would do it. Under normal operation, that button never leaves the cam piston. The plunger spring keeps constant pressure on it. So if the plunger sticks or gets sticky and allows the button to loose contact with the piston it could fall off.Maybe the plunger sticks up and the next time the cam comes around, it hits the button on the side and knocks it off.

- 7,426

- 2,537

- 113

- Location

- Interlachen Fl.

- 114,271members

- 167,174threads

- 2,353,618posts

- 8,270online users