I got a c clamp style press from the auto parts store. I can do wheel studs and small u joints with it. It works great and wont wreck your threads. I used it when I flipped my hubs. I don't know if you will have room to use one on the front without pulling the hub.

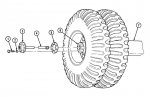

That tool I believe you will find is a ball joint press. (If not, then I'm going to recommend a ball joint press). It will pull and press studs, but make sure you get the adapter kit with it. You may have to improvise an adapter anyhow.

I know the OP said the lug studs are all being replaced, but for the record- Every one of those studs is junk. Their job is to hold the wheel on solely by the clamping force, they should NEVER see a "sideways" load against them. Every time the wheel "flops" and sends one little pulse of the vibration up through the truck, the truck is being dropped from one stud to the next. This bends them back and forth, just as you would do if you were trying to break a coat hangar wire. Bend it a couple of times, and it breaks. The bend here is a lot less, however if you count the number of "thumps" that make up a vibration, each one has been bent a LOT of times.

The wheel and lug nuts obviously need to be investigated for 100 percent proper contact between the lug nut taper and the tapered seat upon which it should sit. If it doesn't sit square and properly ALL the way around each hole, it will not stay seated properly at all.

Final tip, and this is kind of important. If you suspect that your lug nuts are installed too loosely, or "could be" installed too loosely due to inadequate or barely adequate equipment, the lines work great. Lug nutss that do not reach an adequate torque will unscrew. The failure mode is that the lug nuts back off, allowing the studs to receive a shear load that they can't take, then the studs fail. HOWEVER... If the lug nuts are overtightened, the failure mode is different, the stud fails first WITHOUT the lug nuts backing off, and odds are that the lines will never tell the tale.

Lines are great because that type of failure usually happens over a very short period of time. If humidity is low you may never see any visible sign. Stud failure (aside from actually snapping one off with a one inch (or quality three quarter inch) impact wrench, that failure takes a bit longer, and will USUALLY be there long enough to leave a visible sign. Never stop checking for cracked paint and that special color of powdery fine rust that emanates from a loose wheel nut.