dmilkman589

Member

- 181

- 1

- 18

- Location

- troy, ny

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

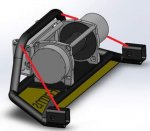

Would there be a market for this anywhere? The winch and the fare-lead are just for representative purposes obviously, but if I started popping these mounts out does anyone think they would sell? Slides right in place of existing lift hook mounts. View attachment 527113View attachment 527114View attachment 527115View attachment 527116

I agree with MarcusOReallyus and I really like his suggestions, not just a "it's weak".Add a brace like below, and now you have a very strong design. Now that angled load is being carried along two lines, instead of being concentrated on trying to pull one weld apart. One line is in compression (VERY strong), and one is in tension (also strong). The force on that lower weld is a shearing force, against which a weld is VERY strong.

Those braces will make good handles, too.

Add a few gussets in some corners (especially that rear tube), and you would have a very nice setup.