res0wc18

Member

- 552

- 2

- 18

- Location

- Everett, Wa

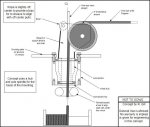

so guys as some of you know i am working on a rear hitch setup, since i successfully installed my hidden winch. Well what i want to do is mount a hitch with something like this built into it so the winch in-line so it can swivel about each direction and drag or pull something in 180 degrees of the bumper. here is the particular thing im talking about FX Skidding Winch Features - Snatchblock Pulley System - Wallenstein

http://embmfg.com/images/products/winches/FX120_Studio_Shot_Large.jpg

That snatch block pulley system is basically what i want to do plus have my receiver mount to hook up a trailer to. Any one know where to buy something like this or have any ideas? I can build everything else except i need to no where to buy the block and pulley?

My winch is hidden behind the bumper and the fair lead is mount right about the receiver mount. I want to be able use the winch and receiver hitch at the same time.

Hope this makes sense...Thanks

http://embmfg.com/images/products/winches/FX120_Studio_Shot_Large.jpg

That snatch block pulley system is basically what i want to do plus have my receiver mount to hook up a trailer to. Any one know where to buy something like this or have any ideas? I can build everything else except i need to no where to buy the block and pulley?

My winch is hidden behind the bumper and the fair lead is mount right about the receiver mount. I want to be able use the winch and receiver hitch at the same time.

Hope this makes sense...Thanks