- 128

- 220

- 43

- Location

- Florida

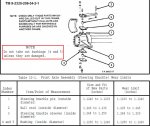

I’m doing my first front axle service on Deuce 1 and found I have the older style ball and claw axles. Ive learned that they use a different retainer than the newer u-joint axles. I have 2 different retainers installed. One with a flat side facing out and one with a stepped side facing out. Not sure if I’ll need to replace one to the old style so they match?

Any info on these older style axles is appreciated . I’ll be looking through old posts over the next few days for more info as well.

I tried a metal rod and pvc to knock out the seals... didn’t budge at all, will be trying a slide hammer tomorrow.

A few other interesting finds - the drivers side lock tab wasn't locked at all and one of the boot retainers was broken and bent in between the boot and axle. Also, 2 of the spindle studs were hardly screwed in. A few turns and they came right out.

I’ll get more pictures posted tomorrow. Ran out of steam tearing into the truck for the past 2 days.

Any info on these older style axles is appreciated . I’ll be looking through old posts over the next few days for more info as well.

I tried a metal rod and pvc to knock out the seals... didn’t budge at all, will be trying a slide hammer tomorrow.

A few other interesting finds - the drivers side lock tab wasn't locked at all and one of the boot retainers was broken and bent in between the boot and axle. Also, 2 of the spindle studs were hardly screwed in. A few turns and they came right out.

I’ll get more pictures posted tomorrow. Ran out of steam tearing into the truck for the past 2 days.

Attachments

-

165 KB Views: 33

-

183.7 KB Views: 32

-

154.2 KB Views: 31

-

172.2 KB Views: 26

Last edited: