- 181

- 106

- 43

- Location

- Wisconsin and Illinois

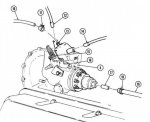

Just wanted to confirm the way the HMMWV shuts down is by de-energizing the fuel shut off solenoid on the injection pump??

I'm assuming this as there are no other electric parts other than glow plugs and starter on startup. But once started there is nothing else electrical keeping it going??

Also, how often does the fuel shut off solenoid need to be serviced/replaced?

Is it a good idea to replace it to avoid future issues?

Is it easy to service in the field if it goes bad?

How do you troubleshoot it's function other than making sure it is getting 24V? My understanding is that it is a mechanical part that is activated by the solenoid. I have this from one of the manuals but other than listening for a 'click' it doesn't look like there is much more. Maybe that is it.

I'm assuming this as there are no other electric parts other than glow plugs and starter on startup. But once started there is nothing else electrical keeping it going??

Also, how often does the fuel shut off solenoid need to be serviced/replaced?

Is it a good idea to replace it to avoid future issues?

Is it easy to service in the field if it goes bad?

How do you troubleshoot it's function other than making sure it is getting 24V? My understanding is that it is a mechanical part that is activated by the solenoid. I have this from one of the manuals but other than listening for a 'click' it doesn't look like there is much more. Maybe that is it.

Last edited: