OK, I need some clarification on timing one of these.

Backstory: My '87 M35A2C w/LDT was brewing it's own oil. Tested the booster pump right before 13SSGR and found it was leaking, so I replaced the seal. Truck continues to brew it's own oil, so now I am removing the flame heater & replacing all the HH o-rings (FDC already bypassed).

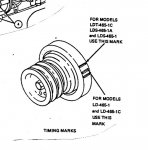

I read the TM and some of the threads about it and thought I had all my info. Rotated the engine around until the red mark was near the pointer, removed the head and then had an accident where I moved the gear on the HH. And of course, I can't remember exactly where the red/scribed tooth was relative to the pointer.

So how do I retime it?

I see in the TM for troubleshooting the LDS-465 Multifuel that it says "With the LDS-465 timing pointer on the harmonic balancer lined up with the pointer, check to see if the timing mark on the advance unit hub is aligned to it's timing pointer. If these are lined up, (paraphrasing) check the scribed/red tooth on the HH and

if it's visible, the IP is timed correctly".

If it's visible? It's probably visible for 40° of rotation? Heck, it could be 10 teeth off and stilll be "visible"!

So now, I am not sure I have the HH back in place in the right tooth. I could be off 1 tooth in either direction.

How do I verify I have it timed correctly? I see the above posts (#5) saying to get the engine at TDC on the compression stroke to see if the scribed tooth is one tooth off, but how can that be seeing where my crankshaft is relative to TDC? This is where I am at now:

I know I am close on the HH teeth, so if I rotate the engine around to TDC, then the HH teeth will be way off and I won't be able to remove and re-time the HH.

What am I missing?